Do-it-yourself staircase

A staircase is an obligatory architectural element of multi-storey and attic houses, providing communication between rooms located at different levels. First of all, she is obliged to guarantee comfort and safety, and secondly, to fit into the compositional picture of the interior. Without observing the rules and without making calculations, a staircase with own hands will be built at least unsuccessfully, it will require global alterations and costly modifications. To eliminate the need to improve an unsuccessful attempt, it is better to do everything initially, focusing on building codes.

Content

- Which staircase we will build?

- Arguments for choosing a staircase material

- The simplest design

Which staircase we will build?

The simplest solution will be modular stairs – with your own hands they only need to be assembled from the completed parts, strictly following the manufacturer’s instructions. Ready-made kits are supplied for assembling mid-flight and screw versions, equipped with a full range of mounting and structural components.

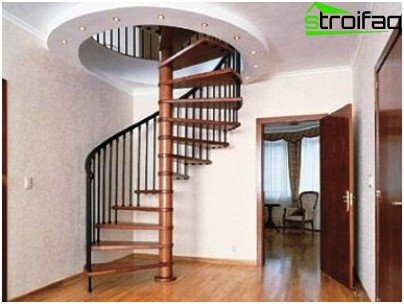

The spiral modular staircase is assembled according to the principle of a children’s designer of their constituent elements fully prepared for installation

Arguments for choosing a staircase material

To build a welded staircase from metal, the skills of a welder and an inverter apparatus are necessary. You can learn the basics of welding yourself, but to build a presentable design, the initial course is not enough. The pouring of concrete structures is often predetermined by operating conditions. Stairs made of concrete equip two, three-story mansions of brick, foam blocks, gas silicate panels. In addition, a cold concrete structure will still have to be lined with wood or lined with other material. The result is that you have to do double work.

The construction of a concrete staircase with wooden lining for financial and labor costs is equivalent to the manufacture of two separate structures

Attention. In two, three-story cottages, according to fire safety requirements, it is necessary to install concrete or metal stairs that guarantee evacuation from the upper floors in case of fire.

For those who need attic staircase do it yourself built in a country wooden house, it is worth choosing wood. The material is lightweight, easy to process, will not push through the floor.

Tip. For the arrangement of new low-rise wooden buildings, staircases from wood are recommended due to post-construction shrinkage. It is difficult to predict how cm the height of the ceilings will decrease, and what the difference will be between a concrete or metal staircase and a ceiling.

There is a lot of useful information about how a staircase is made of wood with your own hands: video courses, step-by-step descriptions. Probable mistakes made in the manufacture of wooden structures, it will be easier to fix. Ultimately, a complete alteration will not be too costly, and the elements remaining after an unsuccessful attempt will always find application.

The simplest design

For those who want to learn how to make a staircase with their own hands for the first time, and to realize the idea, no one will advise you to start with a complex screw type. If the limited dimensions of the room do not allow you to choose a simple gentle option, it is better to purchase a ready-made set of modules or contact the builders.

A gently sloping “means of interfloor communication” will take up a lot of space, but the ascent and especially the descent along it will be the most comfortable. It is optimal that the angle of inclination does not exceed 37 ?. Tilt at 45? automatically translates the design into the category of added. It will be necessary to go down on it with your back forward. Steepness at 40? also not too convenient for descent.

A flat staircase with an inclination angle of not more than 37 degrees is the most comfortable and convenient design, its drawback is that the construction area is too large, if there is not enough space for its installation, you will have to build a staircase with two marches or a spiral

If the question “how to make a staircase on a space limited in size” is firmly set, you should give preference to a two-march building with a landing or with running steps.

Attention. Between direct marches directed towards each other, the distance should be at least 100 mm.

We build a staircase with our own hands without errors: between the marches going “towards” each other, you must leave a distance: minimum 10 cm, recommended 15 cm

The steps of the stairs can rest on the supporting beams-kosour, can be attached to the wall with bolts-bolts, can join two side bowstrings. Consider an example of building stairs with braids.

We build a staircase with our own hands

Regardless of the presence or absence of experience, making a staircase with your own hands, any master should start with calculations and design. The project should focus on safety and creating the best conditions for moving.

Design and project requirements

- The design must hold a load exceeding the average weight of a person with an average build.

- The staircase must be equipped with fences, the location of which must be taken into account at the stage of project creation.

- Fences need to be equipped with handrails and balusters, the distance between the next balusters should be less than the size of the child’s head.

Note. To protect the staircase in order to prevent situations threatening users can be done not with balusters, but with a continuous “cloth” made of plexiglass or mesh, if there are small children in the house.

- The height of the structure is calculated by the finishing floors of both floors or by their estimated marks.

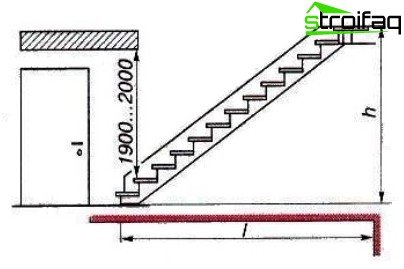

It should be noted that the height of the structure is calculated on the finishing floors of both floors, and the height of the aisle should be more than 5 cm in height of the tallest member of the family

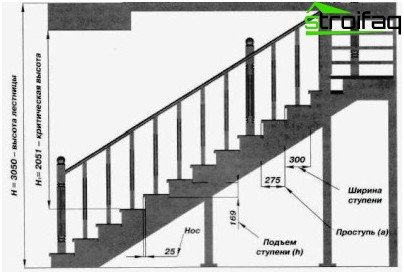

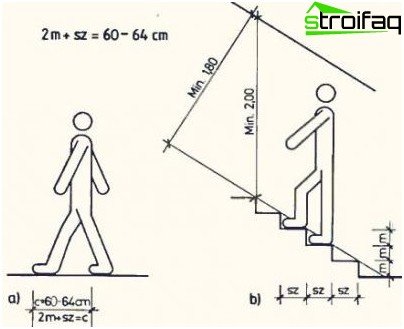

- According to standards, the sum of the tread width and the corresponding riser height should exceed 50 cm (slight deviations are possible). The riser height is recommended within 14-17 cm, the tread width is 25-32 cm for a full foot support.

- The height of the passage is 1.9-2.0 m. The size depends on the growth of users, calculated taking into account the growth of the highest family member + 5 cm.

- The comfortable width of the internal staircase is the distance between the wall and the handrail or between two handrails 0.90 – 1.00 m.

The principle of calculating the steps is based on a simple formula: the sum of the riser multiplied by two heights and the width of the tread should vary between 60 – 64 cm – A simpler option is to add the height of the riser with the tread width, the sum of which should approximately be 50 cm

Design is the most critical step in the construction of a staircase. Mistakes made in the process will turn the construction of the stairs with your own hands into a waste of time, effort and money. Projects of all staircases are carried out by analogy, regardless of the selected material, the rules and calculations are identical.

We will prepare the necessary material

We finally decided that we are building the staircase with our own hands from lumber. For the manufacture of kosour, a pine board with a width of 40 mm is suitable. Risers, which you can refuse to install, can also be made from conifers. Optimally if treads are made of hard wood.

Tip. It is better to buy ready-made steps from glued wood, created like glued beams from bars with different directions of fibers. They will not deform, crack, crack.

Correctly make skewers

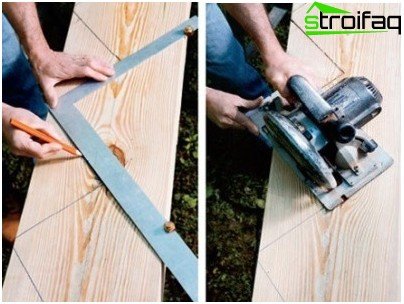

According to the projected dimensions of the steps, draw a pattern. Then we put the markings on the boards and use it with a jigsaw to cut out the peculiar teeth. Those who wanted to know how to build a staircase with their own hands without errors and alterations, probably guessed that all the elements should be symmetrical. So, the first sawn beam with teeth will serve as a template for the manufacture of the second, and if the width of the stairs is 1.20 or 1.50 m, then the third.

You need to start with the manufacture of kosour, for the production of which you will need a template with the exact dimensions of the step, after which the teeth are cut out in the beam to set the steps

Installation of step elements

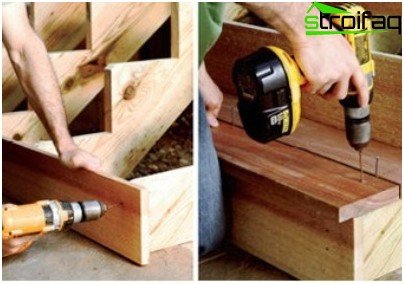

Treads and risers are attached to the scythes with nails and self-tapping screws. The master, who decided not to use ready-made factory components, will also need to saw out these elements according to the patterns made especially for them.

Elements of steps are fastened with nails and self-tapping screws, the tread can be composed of two boards

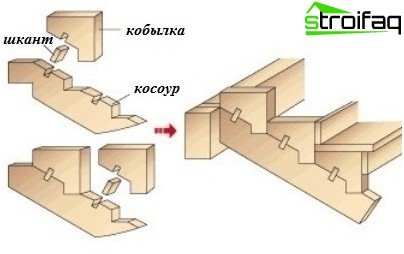

More reliable is the structure, on the supporting beams of which simple triangular or more complex filly are first installed. For their installation and fastening will require dowels and pre-made grooves.

Schematic: how to make a ladder with more reliable curly wooden filly

Install balusters and railings

To install each baluster, we will use an anchor or a hairpin. First, according to the marking, “push” the pin with glue on the glue with the end, which through the tread will then penetrate into the braid, then we will twist it and probably the baluster on the free end. In the same way, posts of fences are installed, between which balusters are placed. At the end, the posts and balusters are equipped with handrails..

Rules for installing fencing elements: according to the exact marking, “pins” are attached to the glue, then they need to be twisted, and a baluster should be screwed to the remaining end

The process of building stairs yourself cannot be classified as simple, but it is not an extremely complex task either. The main catch in competent design. And then pedantry and accuracy should lead the performer, and everything will surely work out.