DIY wooden stairs

When it comes to wooden staircases, most of us, impressed by the unique aesthetics of natural materials, would never even think of calling a wooden staircase a mere construction for communicating floors. Rather, it will be called a significant element of the interior, decoration of home decoration, almost a symbol of respectable life! Indeed, curved wooden handrails on wrought iron railings of stairs or fancy carvings on balusters can be very effective, but is it worth mentioning the unique texture of natural wood, the natural pattern of tree rings and stunning shades of color? Wooden staircases are surprisingly diverse – a photo collection of the most interesting options in our opinion is proposed below. It is quite difficult to do the wooden stairs shown in the photo with your own hands, because in addition to certain knowledge of wood processing, the ability to design and calculate the structure, you will need expensive woodworking equipment.

The manufacture of stairs made of wood requires the implementation of engineering calculations, because the staircase carries a certain load, it is important to consider its location, configuration, angle.

Perhaps a different arrangement of wooden stairs. There are stairs made entirely of wood, as well as containing a metal or concrete base, sheathed in wood from the outside. A metal staircase with wooden steps and railings can be decorated with a wrought pattern instead of balusters. Wooden steps for stairs can also be different not only in size, but also in shape, as, for example, in the case of designing a swivel stair.

Any staircase, regardless of the type of structure and the material from which it is made, includes the main (bearing) and additional (decorative) elements. The main elements include steps, braids, bowstrings, support pillars. To decorative – balusters, handrails, risers, fittings, decorative consoles, etc..

Structural elements of a wooden staircase

When choosing a staircase with a complex configuration, be prepared for some difficulties in everyday life: for example, it will be difficult to move bulky furniture along the stairs. Do not save on fencing, rarely placing balusters: the safest distance is not more than 15 cm.

Consider the design features of various types of wooden stairs.

Classification of stairs by construction method

- marching;

- cantilever;

- spinal;

- screw;

- combined.

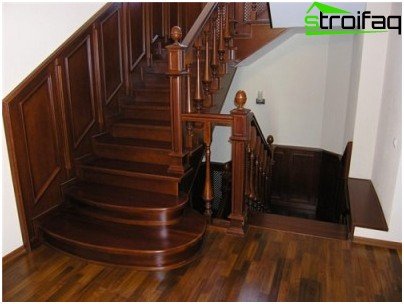

Marching stairs

Marching stairs made of wood are distinguished by the simplest construction, consisting of separate marches. Such stairs can be both straight and rotary. You cannot name a monolithic staircase with straight marches of “wooden” in the literal sense of the word: railings, balusters and steps for stairs made of wood, and the base is concrete.

One of the options for the marching staircase

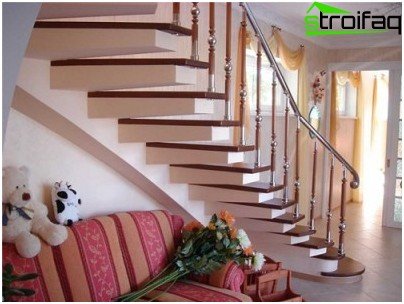

Cantilever stairs

The design of the cantilever staircase is more complicated, the location along the wall and the absence of massive handrails and visible supports create the imaginary impression of a “hanging in the air” design. In fact, the reliable fastening of wooden steps with anchors to the supporting wall provides the necessary stability and strength. Replacing the flooring in a room with such a staircase does not require dismantling it, which can be called an indisputable advantage.

Despite the apparent weightlessness of the structure, the cantilever staircase is durable and stable.

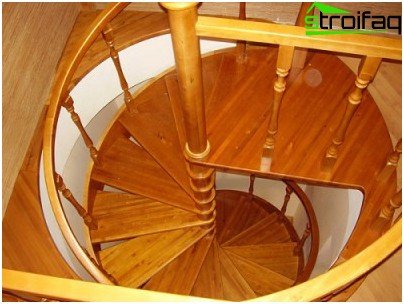

Spiral staircases

Spiral staircases cannot be called the most convenient in operation, but this option is most suitable for rooms with a lack of space. Combined stairs usually include elements of curved, straight and spiral flights.

The original design of a spiral staircase is appropriate in a high room with a lack of space

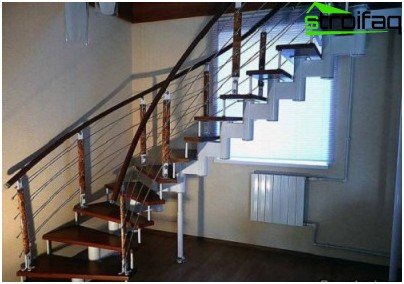

Spinal Stairs

Spinal staircases are named for some resemblance to the ridge: indeed, a structure consisting of separate elements connected by sequential insertion is difficult to name otherwise.

The use of this design allows the alternation of planning decisions (straight, spiral, swing stairs with climbing steps), which makes it possible to get a staircase of almost any geometry. The shape of the fence, of course, repeats the shape of the design of wooden stairs, hence the need for flexible handrails. The manufacture and installation of a wooden spinal staircase will cost one and a half to two times more expensive than the classic version.

The fancy shape of the spinal staircase will decorate the spacious hall

Useful tips on selecting materials and assembling a wooden staircase

Making wooden stairs with your own hands requires careful study of the available information on the topic and a responsible attitude to the selection of materials. When choosing a liquid for tinting, pay attention to its purpose. The choice of a protective or tinting composition designed to protect the tree from moisture and biological effects outside the living room can cause allergies (at best). Varnish and tinting designed for furniture or parquet will be safe for households.

The painting of the staircase parts should be carried out in a clean room, of course, not with a brush, but with the use of a spray gun. Assembling a wooden staircase should be done after painting its parts and after completion of construction work in the room. Using wood in the manufacture of stairs, furniture or flooring, be prepared for the need to maintain a normal temperature and humidity. Otherwise, the material will react to an increase in humidity by deformation of the geometrical dimensions of the parts; from an increase in temperature the tree may dry out.

The manufacture of hardwood staircases is justified, first of all, by the characteristics of natural material: beech, maple, ash or oak wood is characterized by high strength, resistance to shock and mechanical stress, the use of coniferous wood is justified in the case of the manufacture of stairs for a poorly heated country house. Softwoods are cheaper, more resistant to temperature changes, but because of the resin in the composition of wood they are less valuable in decorative terms.

The design of wooden stairs is different in shape, method of attachment, the presence or absence of decorative elements. Studying materials on how to make a wooden staircase, objectively evaluate your capabilities. You can find reliable information on how to make a wooden staircase, but be prepared for complex painstaking work. You will certainly encounter the need for engineering calculations, with the difficulties of choosing the best material for manufacturing, with the subtleties of choosing a color shade in the range necessary for the interior.