Finishing and facing stairs

The staircase should guarantee safe movement and blend harmoniously into the interior. It is necessary to protect the structure itself from premature wear, and to rid the owners of the house of the need to permanently repair the structure and experience discomfort while using it. Rationally solving the whole range of tasks will allow the decoration of stairs, for the implementation of which we apply an extensive range of finishing materials. Let’s discuss the choice of the facing method and find the best option.

Content

- Landmarks in the choice of finishes for stairs

- We choose finishing materials for stairs

- Staircase carpet

- Linoleum, rubber mats, laminate

- Clinker steps, tile, porcelain tile

- Natural stone finish

- Budget Solution – Paint

- Wood and its priorities

Landmarks in the choice of finishes for stairs

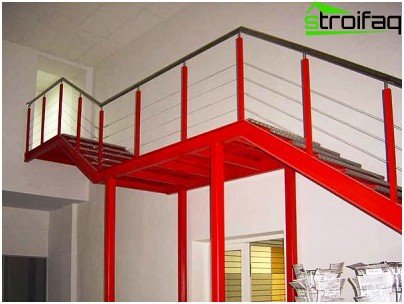

In fact, the staircase lining is a decorative decoration of existing wooden frames, metal structures or concrete marches with landings. The end result should be combined with optimization of operational characteristics and with the formation of comfortable conditions. An important argument justifying the preference for the material and method of implementation is the question of whether the stairs can be finished with their own hands. Summing up the arguments “for” and subtracting all aspects with the wording “against”, the owner will make a competent choice.

The list of arguments for choosing the finishing material includes decorative, insulating qualities, operational safety and the ability to do the work yourself

Basically, the solution to this arithmetic problem is based on three “whales”, these are:

- design configuration;

- preferred soundproofing parameters;

- user contingent.

An important aspect of the choice of material for finishing is the configuration of the structure, the staircase with the running steps is easier and more aesthetically finished with wood.

Possible for independent execution of the method depends on the desire of the owner to finish the stairs himself, from his diligence and the availability of skills. Of course, it is necessary to take into account the staircase and the degree of presentability of the structure in the central or in the economic zone.

We choose finishing materials for stairs

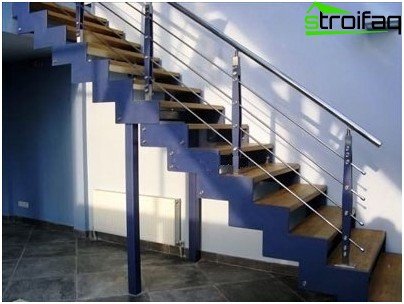

The surfaces of concrete, metal and wooden stairs are finished in whole or in part, a combination of different materials is applicable. For example, the steps of a concrete staircase can be finished with wood, and nickel-plated parts, forged products, glass can be used as a fence.

The cladding of the concrete and metal stairs with wood is perfectly combined with glass fencing

The risers and lateral parts of the kosour can simply be painted, and treads should be faced with stone and laid down a plinth that combines with it. It is possible to finish the stairs with a laminate of wear-resistant 31st class, parquet planks, and any floor covering. The mass of options, consider each of them.

Staircase carpet

It is preferable to trim the stairs with carpet for families with small children, in houses where elderly people live, sensitive to unnecessarily sonorous noise of steps on a stone surface. Carpets often line the central stairs of respectable organizations..

Families with young children and older people prefer carpet trim to stairs, pluses of the cover: lack of noise and pleasant tactile sensations

Elastic soft material does not need to be cut, it is immediately laid. Fastening is made by plastic, wooden plinths, most often brass rods, which must be fixed in the treads with specific clamps. In case of too protruding tread, additional rod rods are used.

To extend the service life of the carpet, felt or similar material is laid under it. Any design can be finished with carpet, fastening folds with studs or bent needles.

Carpeting the stairs: method and devices for laying the roll cover on the rungs

Linoleum, rubber mats, laminate

They cover only tread. Non-slip rubber mats and cut linoleum are attached to wooden steps with metal planks and corners. Corners are used for fastening to the long side of the tread, the strap to the end part. They are simply glued to a concrete and metal surface with a special composition.

Planks and corners are also used for fixing the laminate. To cover the tread, you will need a solid bar, for the riser, the material is cut with a jigsaw along the line marked in advance.

For the facing of the stairs with a laminate, metal corners and strips are used, corners are installed along the long side of the tread, instead of end plates for fixing the material, a plinth can be used

Note. At the design stage, the type and dimensions of the fences, the location of the component parts must be taken into account.

Clinker steps, tile, porcelain tile

Ready-made brick and porcelain stoneware steps with anti-slip coating – a wonderful option, produced by manufacturers for all types of structures. You can now pick up and purchase a complete set for arranging the entire structure with baseboards mounted on the left or on the right. Using a ready-made kit, finishing steps of a staircase is very simple if the dimensions of the elements of the structure correspond to the dimensions of the products. In case of size mismatch, you will have to make a screed with concrete mixture.

Finishing the steps of the stairs with ready-made sets of porcelain tiles is quick and easy, the surface of the steps is equipped with an anti-slip relief

Ceramic tiles will need to be trimmed, which is far from all artists come out aesthetically. For facing a spiral staircase, it is not recommended at all: there will be many ugly seams. Facing direct marches with tiles should start from the bottom step.

It’s quite difficult to accurately tile the steps of the stairs, it’s quite difficult even professionals to refuse to install floor ceramics on the rung

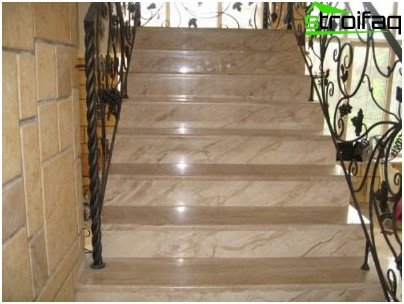

Natural stone finish

It is performed in the same way as the staircase is tiled, because granite, marble, non-porous sandstone or basalt used for decoration is supplied in the same format. Cons of the material in sonorous sound effects from steps and in cost. Porous rocks are too difficult to care for..

Facing staircases with natural stone attracts with operational long-term durability, repels high cost, the need to hire finishers, not everyone is happy with the ringing of steps and a feeling of cold

Budget Solution – Paint

If you are absolutely not interested in the presentable decoration of a staircase made of concrete or metal, if it leads to a basement or to another household room, you can banally paint all components of the structure with a composition with water-repellent properties. The paint will protect the material, but the steps will remain cold. She will not save from sonorous steps. True, if the lining of the steps of a concrete staircase combines dark wooden treads with risers painted with light paint, the design will become more elegant and visually lighter.

Coating is a low-cost, practical solution that protects the material from premature wear.

A ladder made of lumber can be painted or covered with translucent protective and decorative enamel, transparent or tinting varnish, antiseptic impregnation with a coloring substance.

An interesting option for painting a staircase with wooden steps on rails and a metal bowstring

Wood and its priorities

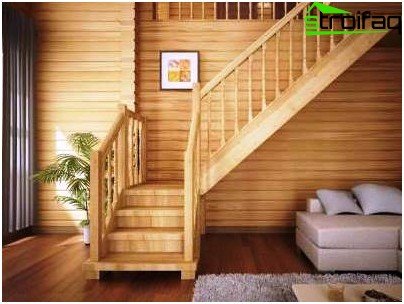

Lightweight material with excellent thermal insulation and decorative qualities can be easily processed, combined with all existing cladding options, looks organically in any interior. Facing a concrete staircase with a tree will slightly increase the weight of an already bulky heavy construction, and will give a respectable appearance to an unattractive building. You can decorate with wood any structure of any configuration, install beautiful fences with curly balusters, use art carvings.

Wood is a material with excellent aesthetic and thermal insulation properties, it is easy to process, slightly increases the weight of the structure

The main plus is that the wood will make the steps warm; without fear, even barefoot can be walked on. Therefore, the owners of suburban housing have the priority of finishing the metal stairs with wood, because it, like concrete, does not please the owners with comfortable heat.

Modular staircase with metal frame with wooden steps

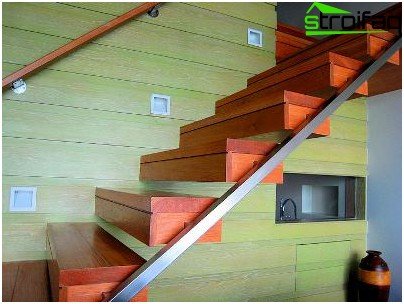

In such cases, either only treads or all the step elements on top of the previously laid moisture-proof plywood are installed on the welded metal ridge. After facing the steps, you can sheathe the entire structure with drywall.

The steps of the metal stairs can be completely sheathed with wood or only wooden treads can be installed

Phased staircase lining with wood

It will be possible to sheathe a concrete staircase with wood almost two months after its pouring. Concrete during this period will release all excess moisture so that the lumber installed on top of it does not warp, do not crumble later and do not deform. The number and complexity of the technological steps depend on the quality of the fill. The full cycle of work on cladding concrete stairs with wood will include:

- Alignment. The surface of the monolithic structure with a fair amount of flaws will need to be leveled. For this, standard methods of leveling the concrete base are used: screed and logs. It takes a week or two to harden the polymer self-leveling mixture, the concrete screed will harden and lose moisture again for about two months. Better to use lags. And they are built faster, and the weight of the stairs will not increase too much.

Important. If the cladding of a monolithic structure with wood was originally planned, when designing it is necessary to take into account the thickness of the finishing material. Special care should be taken when assembling the formwork for pouring concrete stairs, so that it is not necessary to correct the difference in the size of the steps with the help of alignment.

A wood cladding on the steps of a concrete staircase is laid on top of waterproof plywood

- Laying plywood with water-repellent properties on top of screeds, logs or on steps that have been cleaned of growths and plaster. The material must be selected with a thickness of 12 mm, fasten it with a dowel-nails.

- Fixing step elements to plywood. Held with glue and screws.

- According to the marking, a plinth, balusters are installed, then handrails and decorative details of the fencing are fixed.

Most often, the facing of a staircase with a tree determines the use of parts polished and treated with paints and varnishes. However, no one forbids performing paintwork after.

Knowing the technology of lining and finishing of stairs is necessary not only for those who decide to do the work on their own, but also for those who decide to hire finishers and choose the best way of facing. The information obtained will help the owner to identify violations and suppress the desire of workers to save on time and materials.