A reliable roof is one of the indispensable conditions for well-being in the house. That is why for her many people prefer to use metal sheets, the benefit in our time laying rebate coatings has become less time-consuming. And the right roofing tool is now easier to find, not to mention the teams of professionals. But even if you are going to entrust the work to specialists, it’s worthwhile to at least slightly understand the issue yourself – in order to avoid various kinds of overlaps and misunderstandings.

Content

- Seam roof – general concepts

- Advantages and disadvantages of the seam roof

- Basic rules for installing a seam roof

Seam roof – general concepts

The roof covering, made of metal sheets interconnected by a special seam (rebate), is called the rebate roof. Varieties of this type of roof are enough to make an acceptable choice – both in terms of means and appearance. The main division is based on materials and includes:

- copper – premium coating with a long service life and luxurious design

Premium Copper Seam Roofing

- zinc-titanium – a reliable and highly aesthetic roof

Zinc-titanium – a reliable and aesthetic rebate roof

- galvanized steel is the most common material of the end of the last century, unfortunately, not the most durable, but relatively inexpensive

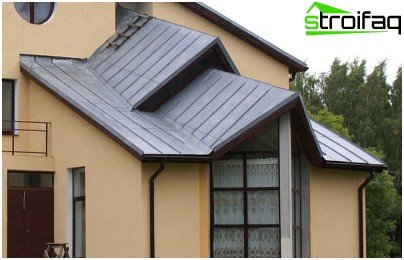

Galvanized steel seam roof

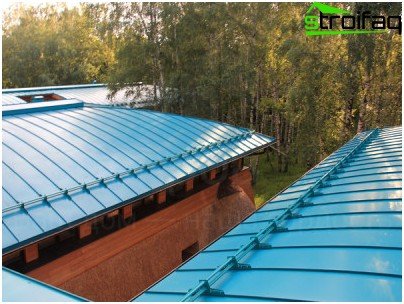

- polymer-insulated steel – a roof with an extensive selection line, both in terms of polymer properties and color gamut

Polymer steel rebated roof

- plain or plastic coated aluminum – lightweight, reliable enough and not very expensive

Polymer coated aluminum seam roof

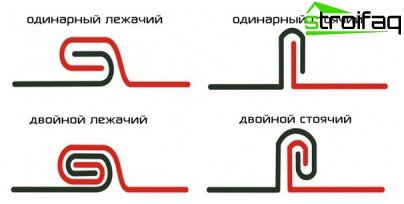

In addition to the material itself, the difference is also in the connection method, where four types of seam are used: single, double, standing and lying. In more detail their device and differences can be seen in the figure..

Varieties of rebate

Advantages and disadvantages of the seam roof

Before you start purchasing materials, you must still make sure that the right choice has been made. So read carefully – suddenly you will learn something new.

The folded roof is considered one of the most reliable roof coatings due to the following qualities:

- the highest tightness of the roof over the entire surface is ensured by a seam seam, as well as a hidden fastening system and the absence of through holes

- strength, wear resistance, durability and anticorrosion properties are achieved due to the material (metal) and its coatings

- folded ribs give additional rigidity to the roofing sheet, they also provide directivity to the descent of rain and snow moisture

- aesthetic appeal and a modern look allow you to complete the roof in any style decision

Advantages include modern technology for the manufacture of sheets of appropriate length with edges immediately bent under the fold, the so-called paintings. Moreover, this procedure can be performed both in stationary production – on order, and directly on the construction site where your house is being built. In the picture – a machine for making paintings.

Picture forming machine

However, like any other material, the seam roof is not without drawbacks. And they include:

- the high price of the highest quality and most attractive external coating (copper and zinc-titanium), which is completely offset by the ability to choose steel or aluminum with polymer insulation

- quite complex installation technology, requiring not only sufficient practical skills, but also the availability of special folding equipment

By the way, the second position becomes absolutely insignificant if you use the help of qualified roofers-tinsmiths who have both experience and the right tool for the seam roof.

Basic rules for installing a seam roof

We will not describe the full installation algorithm here – if such a need really arises, it is better to check with a knowledgeable person who has practical experience. But the main points that are worth paying attention to are described.

So, the installation of the seam cover begins with the preparation of the correct crate, on which the paintings will be laid. Here you need to clearly understand that the strength and durability of the roof itself depends on the reliability of the foundation. Therefore, the material of the crate must be really high quality. If you use wooden bars and boards, then they must be properly dried and saturated with compounds that prevent decay, ignition and insect damage. The crate itself should be frequent enough so that when walking on the roof, thin metal sheets do not deform until damage. In places of the greatest load (edges and bends) it is better to make the crate completely continuous, for example, to make a dense plank flooring or even to lay OSB-plates. If these conditions are violated, your roof will live as long as the crate. Due to the rotten bars, the folded roof will deform, which will lead to a violation of the integrity of either the metal sheets themselves or the seams. Deformation (with subsequent damage) will also threaten with too large a step of the crate.

Laying the seam roof on the crate

In addition, it is better to immediately equip ventilation and moisture and moisture insulation. If moisture penetrates from the house to the inner surface of the roof, condensation can significantly affect the service life of metal sheets, because the main anti-corrosion coatings are applied on the outside of the sheet.

Lining waterproofing

When fixing the roof, the main condition is the use of clamps, self-tapping screws, screws and other trifles from materials corresponding to the metal of the paintings. That is, for a copper coating and a clammer you need a copper one. Imagine what happens if copper is galvanized or vice versa? Yes, yes, the simplest physics is a galvanic cell. It is clear that under such conditions, the folded roof will significantly reduce the service life. By the way, to comply with the installation technology, one more thing must be taken into account. There are two types of clamps – fixed (simple) and floating. If the picture is not too long, a simple clammer is used. However, in the case of very long metal sheets, the fixed clamp can cause significant deformations – since any metal tends to compress-expand when the temperature changes. Then the floating clamp is used, which has a sufficient margin of free play. Both types of clamps can be clearly seen in the figure..

Klyammery – motionless and floating

As already mentioned, the seam seam ensures tight joints between the sheets. The most common (due to increased reliability) connection method is a double standing seam, while a single seam is used only on a simple roof slope with a slope of 14 degrees or more. The recumbent folds are most often used for horizontal seams (joining sheets in length), however, with the roll method, when the paintings correspond to the roof in length, they are practically not needed.

Then follows the very laying of paintings and their folding – high-quality closing of seam seams, which occurs with the help of special equipment: frames for closing the seam. Of course, a qualified roofer will completely close the seam with manual frames, but nowadays automatic equipment has also appeared, which greatly facilitates folding, especially with large roof areas. Violation of folding technology will lead to insufficient tightness of the roof.

And the last moment – the installation of paintings in difficult places. Ends, grooves, pipes for various purposes (from chimneys to ventilation) are arranged in such a way as to preserve the integrity of the overall coating. The device of aprons, overhangs, cornices is not too complicated, but a practicing specialist will deal with this matter faster and better than a beginner self-taught master. Remember that it is in such places that it is most difficult to comply with all installation rules, and any error will lead to loss of tightness.

As you have already seen, only really high-quality work in compliance with all the rules for installing a rebate roof will give a reliable result. Otherwise, get ready to immediately begin repairing the new roof – and in some cases, repair may be more expensive than the initial installation. So it is better to entrust the work to professionals – firstly, there is a greater likelihood of final success, and secondly, in case of an error, it is possible to compensate for it at the expense of the performers. Good luck and a strong roof over your head!