Mineral wool or polystyrene

The ideal building material, as well as impeccable insulation, is a dream that has not yet been embodied in tangible reality. Numerous attempts to create a high-class heat insulator for equipping building structures have not yet led to a productive result. Those who wish to equip suburban housing or a city apartment with a layer of insulation still have to choose, carefully weighing the shortcomings and convincing advantages of each of the materials. Having added a certain amount of negative and positive qualities, the consumer decides whether mineral wool is suitable for him or whether it is better to purchase a lightweight practical foam.

Content

- Mineral wool and polystyrene evaluation criteria

- Mineral wool and its characteristics

- Water repellent and bearing capacity

The work of engineers and chemists working diligently on the invention of impeccable heat-insulating material can still not be called unproductive. The new generation of insulation significantly differs from its historical predecessors in a significant number of technical indicators. In addition to improving technical characteristics, the development area was extended to ensure ease of installation and increased wear resistance. There have been successes, but it is still necessary to choose and evaluate the advantages and disadvantages.

Power of a layer of mineral wool, polystyrene foam and other building materials with equivalent insulation characteristics

Mineral wool and polystyrene evaluation criteria

The buyer, that is, the owner of a residential or commercial property, a country house or small cottage under construction, is interested in such qualities of materials for thermal insulation as:

- minimum operational thermal conductivity, not changing depending on the complexity of the conditions;

- strength, lack of thermal expansion, preservation of structural bonds when exposed to moisture;

- good work in high temperature and low temperature mode;

- low moisture absorption;

- operational long term;

- low specific gravity with high insulation parameters;

- the ability to quickly install in any season, ease of installation;

- resistance to biological effects;

- safety,

- justifying the probability of use for insulation of housing.

A comparative assessment of mineral wool and polystyrene foam for each of the above points will provide an opportunity to reasonably approach the problem of choosing the best material.

For the correct orientation of the selection of insulation, you need to decide which of the indicators for a particular buyer are dominant.

Mineral wool and its characteristics

Stone builders called “mineral wool” stone wool is a heat-insulating material with a chaotic fibrous structure. It is obtained by melting igneous and metamorphic rocks, metallurgical waste and mixtures thereof. The properties and genesis of the rocks used in the production of insulation determines the main advantages of mineral insulation:

- resistance to fire,

- resistance to biological negativity,

- low thermal conductivity.

The most common and popular type of stone insulation in construction is basalt wool and mats made on its basis. Stone thermal insulation can be made of slag, diabase, porphyrite, gabbro and other minerals consisting of silica, including magnesium and iron oxides.

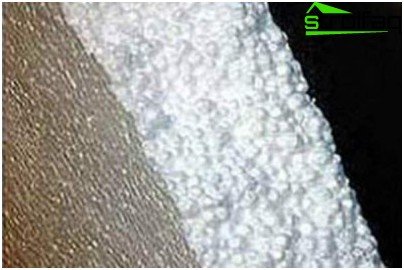

Unique stone wool structure

Mineral heaters do not burn, do not melt even at a temperature of 1000 ° C, have the ability to prevent the spread of fire. Stone wool is an excellent barrier to preventing the passage of thermal energy. True, in a humid environment, mineral wool may lose its characteristics. Porous insulation allows steam to pass through and can absorb moisture. As the amount of water in the material increases, the heat engineering priorities decrease, since water, which is an excellent conductor, contributes to heat loss. But due to the ability to skip evaporation, mineral wool is actively used to equip houses made of wood. After all, the advantages of natural organic organics lie in the ability to spontaneously remove household steam beyond the contour of the building, and any other type of insulation can deprive wood of one of its central advantages.

Water repellent and bearing capacity

In a series of stone heaters, basalt cotton wool is distinguished by the highest water-repellent properties. It passes a minimal amount of moisture, because the material is often used to warm pools, saunas and baths. With its help, thermal insulation of pipelines and utilities is performed. The random arrangement of basalt wool fibers provides high strength, the ability to withstand strong loads.

Based on the strength properties, basalt products are used to equip the lower floor and the interfloor system combining floor and ceiling. For the arrangement of the floor with the same intensity, porous foamed polystyrene and other types of synthetic heaters are used. For those who want to equip the floor with insulation, a natural question arises: “What is better suited for floor insulation: mineral wool or polystyrene?” Definitely no one will answer, but the comparison scales often lean towards stone wool because of the affordable prices and the ability to suppress the passage of sound vibrations. And according to the initial strength parameters, both types of insulation have almost equal indicators.

Mineral wool is more effective material in acoustic characteristics

Quality polystyrene foam performance

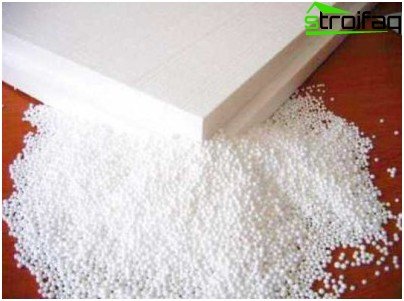

The foam is obtained from a suspension polymer by foaming, which is due to its low specific gravity. A light insulation is distinguished by high strength, since its structure is a lot of small closed cells interconnected in a specific way. Each of the peculiar closed spheres, inside which there is gas or air, takes on part of the load. Together they provide powerful resistance to static and dynamic effects..

Structural strength and reliability in the operation of the insulation is provided by the technology of sintering granules into a monolithic material. The bonds between the granules are not destroyed during the entire period of use. Stone wool products are inferior to foams in terms of long-term durability. During prolonged operation, especially at critical temperatures, even the most wear-resistant basalt wool, which occupies a leading position in the series of mineral insulation, can delaminate, crumble and deform..

The specific structural structure of the foam, justifying its technical advantages

During production foam insulation, 90% consisting of air, form into plates, blocks, modules for fixed formwork, architectural and decorative elements and other types of products. Foam having constructive strength and density is unusually easy to install, due to which the terms of work on the thermal insulation device are significantly reduced.

Operational Safety Issues

In order to combat the combustibility of plastic heaters, their composition is enriched with additives that impede combustion processes. Again the question: will foam or mineral wool provide complete safety? Manufacturers claim that according to the ignition criteria, these materials are equivalent. In the event of a fire getting into the fire source, these two types of insulation work the same way, since they belong to the group of self-damping.

In the production of mineral insulation, phenol-formaldehyde binders emitting harmful volatile substances are used. With the loss of structural bonds, silica-containing cotton wool can also spread silicate dust, which no one has yet invented ways to cleanse the lungs from. Certified heat-insulating mineral-cotton materials, of course, are suitable for home improvement, but handicrafts should be wary. If the foam or mineral thermal insulation acts as the middle element of the well masonry or is placed under a concrete floor screed, the safety criteria do not matter.

Light weight and easy installation

Foam products are significantly lighter than stone wool products. The heavy weight of mineral insulation affects during transportation. The cost of loading, delivering to the construction site, unloading stone wool products is higher than the payment for similar processes required for the transportation of foam products. Lightweight foam insulation is more convenient to install than to install mats from basalt insulation, which affects the pace of work and the payment of expensive manual labor.

New generation non-combustible foam

Thermal insulation made of foam insignificantly increases the weight of building structures, which means that home improvement does not require reinforcing the bearing capacity of the supporting base. When warming a building with basalt wool, its weight will need to be taken into account. Moreover, one will have to rely on the weighting of the mineral material during operation at a high level of humidity, which is why hygroscopic stone wool is less and less used for equipping insulation with basements, basements and foundations in contact with water-saturated soils.

For consumers who want to heat insulation of housing, commercial or industrial buildings efficiently and economically, a comparative analysis of the materials will help to make a choice. There is no single answer to the question of what is better polystyrene or mineral wool. Each of them has its drawbacks and a considerable list of advantages. Focusing on the moments that are important personally for the buyer, you can choose the best option.