Talc Chlorite Ovens

Talcochlorite is a natural stone formed from volcanic lava billions of years ago. In those days, no one could even think (although there was no one to think) that this material in the 21st century would be an ideal assistant for people in decorating apartments, houses, baths, garages and other premises. It looks great both inside and outside the building. And stoves made of talchochlorite have become so popular that when you enter the first sauna or bathhouse you will definitely see this finishing material on the front side of the heater.

Content

- The characteristics of this rock

- Features furnish bath furnaces with talchlorite

- Which stone is ideal for stoves

- How to lay a stone

- Secrets of laying talcahlorite

The characteristics of this rock

Talkochlorite is an environmentally friendly rock that has unique characteristics unique to it.

- High heat capacity – 2.5 times higher than conventional kiln bricks. In two hours of the furnace, the stove accumulates so much heat that it is enough for a whole day, which means that you can save a lot on wood and coal.

- Quick heating – the material heats up about 4 times faster than clay brick, which allows to reduce not only the furnace time, but also reduce the cost of buying kindling material. That is again saving!

- Melting resistance – even astronomical temperatures are not able to affect the attractive appearance of talchochlorite, because, as mentioned above, this rock was formed from lava, the temperature of which is many times higher than that created in the sauna furnace.

- Magnificent structure – luxurious natural stone perfectly emphasizes the beauty and style of your bath.

- Durability – once you finish the stove or fireplace with this stone, you will forget about such work for 20 or even 30 years.

Natural mineral – talchochlorite warms up quickly, retains heat for a long time, improves steam composition

The physical characteristics of talchlorite, of course, are very important, but the fact that this finishing material has a beneficial effect on human health is no less important..

Experts have proved that the length of the heat wave emitted by a heated stone is equal to the length of the heat wave emanating from a person, which means that next to the stove trimmed with talc-chlorite, you will be cozy and comfortable. Thanks to mild heating, immunity increases, blood circulation improves and blood pressure decreases..

Features furnish bath furnaces with talchlorite

In fact, furnace lining Talkochlorite – the process is not complicated and practically does not require any sacrifice. It will take you a little time to finish, and the installation itself is simple to disgrace. Although there are some subtleties and nuances here. We’ll talk about them.

Which stone is ideal for stoves

For facing stoves and fireplaces polished talc-chlorite tiles are used with a thickness of about 40-50 mm and a width of 80-120 mm. The color of the material can be any, the main thing is that its shade be the same.

Smooth talc-chlorite tiles in the decoration of bath stoves

How to lay a stone

Depending on what you want to receive at the exit, talcum chloride can be laid both vertically and horizontally. If you lay the tiles vertically, that is, with the end face, they will warm up to the top much faster, and if you lay the material flat, the heat will not spread along the layers, but across, which will slow down the heating process.

Finishing the walls of the bath with talcochlorite – an unlimited number of options for horizontal, vertical, asymmetric cladding

Horizontal masonry tile

Secrets of laying talcahlorite

And they are not, because in order to keep the tile, you just need to use a special glue that smart Finns invented in the last century. It is prepared from talcum chloride powder and liquid glass. It is this combination that provides the necessary strength and durability.

Due to the fact that cement mortars are not used when finishing the furnace with talchlorite tiles, your bathhouse will remain clean, because there will be no dust and dirt during operation.

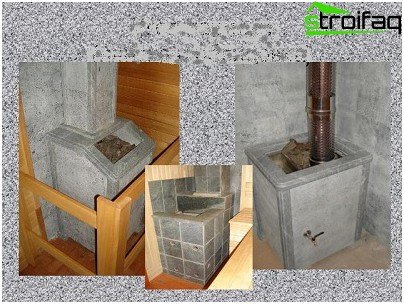

In the manufacture of a furnace made of talchochlorite, it is laid horizontally, since in this case the furnace will heat up faster, but for facing the stone is sawn in the opposite direction (across the fibers), so quick heating will be combined with uniform and slow heat transfer, providing your sauna with heat for whole day.

Tiles are laid one on top of the other, and they need to be fixed with a special bracket or pin so that they do not fall off under their own weight. After the adhesive solution has dried (after 2-4 hours), the staples are removed, and the gaps between the tiles are filled with grout.

Talkochlorite stove is the dream of any attendant

Sauna stove made of talchochlorite, is able to maintain a stable level of temperature and humidity in the steam room of the bathhouse or sauna. It is this natural mineral that avoids such a problem as a cold stone with boiling water in a tank. Due to the large mass of talcochlorite around the furnace and on the walls, the bath heats up much more evenly, and the quality of the steam itself is much softer and enveloping.

The surface temperature of the sauna stove made of this material and the heat filling the steam room are ideal for the initial heating of the human body. Entering the bathhouse, you will immediately feel how deeply the warm wave emitted by the stove penetrates into the body.

The use of talcochlorite in the decoration of walls and furnaces: the heat source itself and the area around it

The furnace and the adjacent wall are finished in talcum chloride.

Given all the features of talcum chloride, only one conclusion can be drawn – the stove, trimmed with this mineral, will become a real masterpiece, a work of art worthy of applause and admiration. Beauty will certainly save the world, and the warmth presented by the stove will save you from many health problems and depression.