Do-it-yourself bath stoves

For the Russian people, the bathhouse is a mother, and baking her kind warm heart. Without healing heat and steam cleansing the body, created thanks to the operation of the bath furnace, traditional hygiene procedures are not feasible. The stove is the central organ of any bath of the Scandinavian, Roman, Russian, Turkish type. Only the purchase of the main component of the bathhouse of passionate fans of vigorous steam does not always have an unnecessarily high price. But the oven for a bath with their own hands is quite capable of anyone who knows how to hold purely male instruments in their hands and remembers their purpose.

Content

- About metal bath stoves

- The main structural components

- Pipe as a blank for the manufacture of a furnace

Home-made and factory-made bath stoves simultaneously perform two important functions. Their task is to heat air in hygienic rooms and water for bath procedures. The principle of operation of industrial and do-it-yourself equipment is the same, similar designs. True, a homemade stove for a bath is not equipped with so many technical “bells and whistles” and significantly loses in design. But a carefully crafted homemade product will perform its work flawlessly and will not disappoint the owners.

Budget option for bath equipment: homemade oven

About metal bath stoves

For the construction of a bath furnace, brick or metal is usually used. The latter option is preferred because of the simplicity of the full range of work and the speed of production. An important argument in favor of the simplest metal furnaces is the availability of prices for the material, and sometimes a completely free piece of durable rolled metal, a metal sheet or a barrel.

Advantages that distinguish home-made metal stoves for a bath against a background of analogues:

- heat resistance;

- operational wear resistance;

- the ability to heat the bath in the shortest possible time, ranging from 40-45 minutes to 1.5 hours (the duration of the heating period depends on the climatic season and atmospheric temperature);

- an extensive range of designs of heating systems with different heat capacities, due to which it is possible to equip both a small family bathhouse and a large building;

- the ability to use any type of solid fuel and heat the furnace during the adoption of bath procedures.

It is convenient to load a home-made oven, you can heat it during washing with any kind of solid fuel

Relatively light metal home-made stoves for a bath are easy to install, do not require the installation of too powerful support base. However, they also have disadvantages. Metal heating units cool down quite quickly, which helps to fight the ability to heat the furnace during the entire time spent in the bath and the brickwork around the equipment. The heat from the metal system is distributed unevenly, which does not particularly bother the owners of small baths. Well, a large bath can be equipped with several homemade products located at a distance dictated by technical requirements and fire safety rules.

The main structural components

Favorite Russians “Kamenka” constructively represent a building divided into functional components. Those who want to make a good sauna stove with their own hands should know that the main elements of standard heating equipment are:

- firebox;

- an open or located inside the case container for bath stones;

- ash-pusher;

Design standards for metal bath furnaces

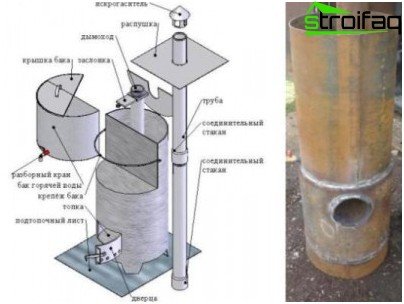

Between the firebox, stones and the blower are installed grate-grates. The water heating tank may be part of the housing or located on special supports above the tank with bath stones. It can be installed separately in the dressing room and connected to the heat exchanger via metal pipes or rubber hoses. The equipment must be equipped with a chimney that displays fuel combustion products outside the bathhouse. In order to prevent quick cooling around a metal furnace or only around a furnace, refractory brickwork is performed.

Pipe as a blank for the manufacture of a furnace

Those who wish to make heating equipment out of metal quickly and reduce the amount of work will be helped by a kind of billet, which is a steel pipe with a half-meter or other diameter. Home-made stoves for baths can be made on the basis of a vertically located pipe or a horizontally directed segment of wide pipe hire. For the manufacture of equipment will require significantly less welding work than in the manufacture of stoves from a metal sheet. It is important to initially check the reliability of the workpiece and identify the presence of corrosion damage if the metal product has been lying on the street for a long time. It is better to immediately strengthen all problem areas with specific welded “patches” or cut functional stove holes in this place..

Manufacturing sequence

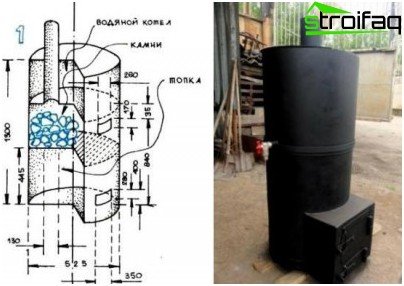

In order to make the simplest furnace in the bathhouse with your own hands, you will need one and a half meters of rolled pipe with a diameter of 50 cm with a wall thickness of at least 10 mm. The pipe is cut into two unequal parts:

- in the first part, the length of which is 90 cm, a stove and a firebox will be equipped;

- in the second part with a length of 60 cm a water boiler will be arranged.

It is required to approach the work on manufacturing a sauna furnace with the utmost scrupulousness. The slightest flaws can turn into disastrous consequences.

In the best case, a home-made metal stove for a bath simply will not function fully or will pass water into the furnace. The worst option could be carbon monoxide poisoning..

Homemade metal pipe stove: arrangement of structural elements

- Let’s start with the blower. It needs to be cut from the bottom side of the larger part of the future stove, that is, at the base of the created unit. The width of the hole is not more than 20 cm, the length is approximately 6 cm. To install the grate in the pipe, it will be necessary to cut a groove, and equip the grate-grate with durable fasteners such as welded steel ears.

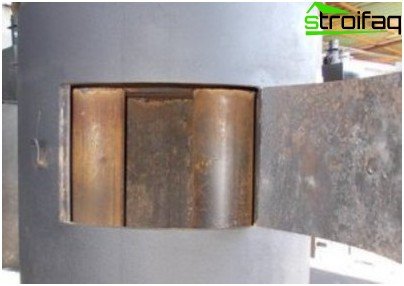

- A niche for the furnace is cut out. Its horizontal dimensions are 30 cm, vertical 25 cm. A neatly cut piece of metal will subsequently become a firebox door. It is necessary to attach a handle, a latch and hooks to it, loops for which are welded to the stove body in appropriate places. The firebox window is located at a level convenient for the owner. After all, focusing on personal physical parameters is one of the advantages that makes a homemade stove in a bath.

- The heater is equipped directly above the firebox. To make it, you will need a pipe with a diameter of 30 or 35 cm. To insert a scoop-shaped device made from this pipe, you need to be perpendicular to the walls of the stove pipe. One end of the stove-scoop, necessary for laying stones, is closed by a door, the opposite end is tightly welded to the wall of a metal furnace. From the top level of the heater to the future location of the water tank there must be at least 10 cm.

- The upper part of the stove is equipped with a steel coupling, it will become an auxiliary fixture for installing the boiler.

- The bottom of the water tank is made of steel sheet with a thickness of 8-10 cm. It will be a circle in which to make a through hole for installing a chimney. The chimney must be firmly welded to the edges of the hole. If the docking is leaky, water will leak into the firebox, it will begin to flood. The pipe performing the function of removal of combustion products will pass through the tank with water, heating it.

- The finished design, which is a water tank, is hoisted into a part that includes a firebox with a heater. Two parts of the sauna stove are welded. The top of the heating equipment remains open, which is necessary to fill the tank with water. In order for the water tank to be closed, you need to make a lid with a handle.

- In the lower part of the water tank there is a faucet with a valve for taking hot water.

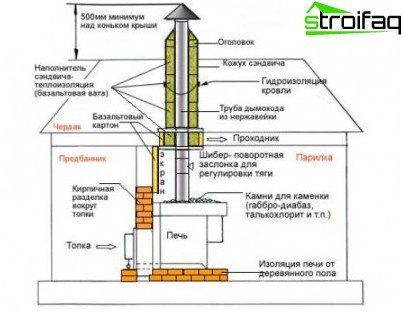

- A steel square plate with a side size of 30 cm is welded to the chimney at a distance of approximately 35 cm above the upper edge of the tank. It is needed to make brickwork around the chimney passing through the ceiling, the attic and the roof of the bath.

Installation Specifications

Regardless of whether the stoves were made for baths with your own hands or purchased in a specialized store, installation of equipment must be carried out in strict accordance with the listed fire safety rules.

- In baths with internal wood veneers, stoves can be placed at a distance exceeding 1 m from any wall.

- The distance between the heating unit and the chimney must be kept to a minimum..

- The distance between the stove and the wall can be reduced to a minimum of 20 cm if the wall is lined with metal sheet, refractory bricks or coated with plaster.

In order to optimize the circulation of the air flow, the furnace is installed on a specific foundation 20 cm high from the floor. It is made of brick, foam concrete slabs or other non-combustible material. It is advisable to secure the fuel loading zone by laying a metal sheet 50 × 70 cm in size in front of the firebox. The firebox doors should be placed in the direction of the doorway, the heater doors in the opposite direction.

Proper installation of the chimney

Those who make bath stoves with their own hands are required to follow technical recommendations. It is necessary to know that a metal chimney is recommended to be equipped with thermal insulation from stone wool, expanded clay or other non-combustible materials. The thickness of the insulating layer, eliminating the appearance of condensate, varies from 8 cm to 12 cm. Chimneys are placed in any priority place for convenient safe operation inside the bathhouse. To prevent the pressure of the mass of the chimney pipe on the furnace, it must be fixed inside the ceiling.

Rules for technically competent installation of the sauna stove

According to construction requirements, the chimney should rise above the ridge of the roof, and the chimney should be raised at least half a meter above the flat roof. A section of the chimney passing through the attic space or attic should not have openings for cleaning, dampers or additional views. According to technical requirements, the chimney should not have horizontally directed segments whose length exceeds 1 m.

The cheapest heating option – homemade stoves for a bath, a photo selection may not be presented as an aesthetically attractive element of a presentable bathhouse. Their dominant advantage in the budget price of raw materials and the ability to make a functional unit on their own. In addition, it does not take a long time to collect the amount necessary for the purchase of an expensive heating installation, endlessly delaying the start of operation of the bath for an unlimited future.