Drywall is a unique material that allows you to create amazingly beautiful designs and smooth complex surfaces. It has heat-insulating properties, absorbs moisture, and is characterized by properties such as fire resistance and strength. It should be noted that the alignment of the walls with drywall is much faster than with other finishing methods. When carrying out repairs, some features specific to this material should be taken into account..

Content

- Dry alignment methods.

- Features Alignment Using Wireframe.

- The specifics of drywall mounting without a frame.

- The final stage – putty

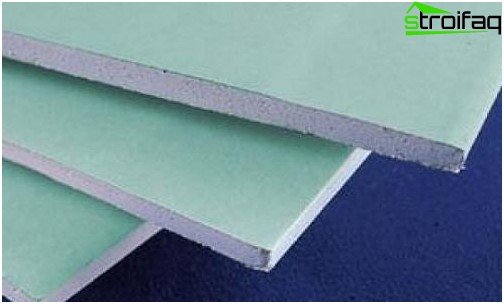

Modern technologies make it possible to produce not only traditional and fire-resistant gypsum plasterboards, but also moisture-proof, which allow alignment of walls even in rooms with high humidity.

Moisture-resistant drywall

The process of leveling walls with drywall is the optimal solution for walls with large irregularities and level differences.

Also, this method is often used to organize a completely flat surface, designed for gluing walls with wallpaper or for painting..

Dry alignment methods

In practice, two methods are used that allow you to align the walls with drywall with your own hands:

- Installation of drywall sheets on a frame assembled from a wooden beam or metal profiles;

- Drywall installation using special glue.

Each method has its own characteristics that determine the choice of a particular installation option in a particular situation..

Features Alignment Using Wireframe

If there are significant irregularities on the surface of the walls, it is better to use leveling using a frame. It can be assembled from metal or wooden beam profiles..

The wooden frame has several disadvantages: a more complex manufacturing process technology, the need to use well-dried wood, as otherwise the frame will lead and cracks will begin to appear on the surface of the drywall.

The timber for the timber frame must be well dried, otherwise deformation cracks will appear on the level surface

Based on this, for rooms of high humidity, a frame made of metal profiles must be used.

After choosing the method, it is necessary to predict the maximum load that the repaired wall will have to withstand. Places of increased load need to be strengthened with the help of mortgages from plywood or boards.

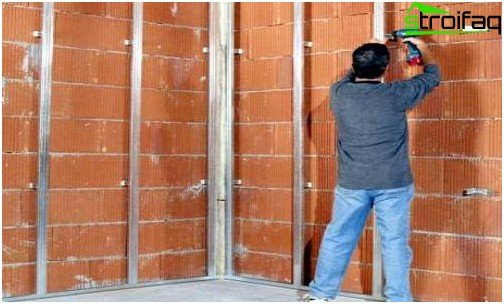

The use of metal profiles allows alignment of walls of any shape and design. For work, you need a guide and rack profile. Guide profiles are placed in a horizontal plane, attaching them to the floor and ceiling in parallel lines. First of all, the profile should be screwed to the ceiling surface, then with the help of a plumb the profile is attached to the floor with strict observance of the level. Rack-mounted racks with a gap of 0.4-0.6 m are inserted into the fixed guide profiles.

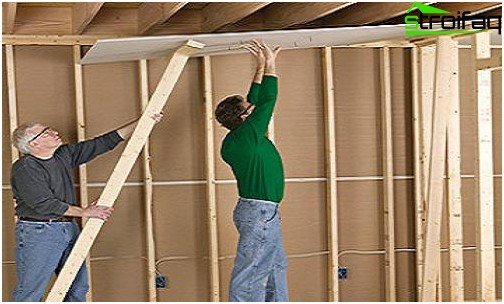

Using drywall attached to a metal frame, you can level absolutely any surface

Depending on the available wall height, the profile must be shortened or lengthened. A feature of this method of leveling the walls is strict adherence to the vertical orientation of all profiles, which is determined by the level when it is applied to the end of the metal profile. To ensure the quality of the assembled frame, it is necessary to mount the rack profiles by suspension.

It is important! If there are water or steam heating pipes in the room, special sleeves should be installed at the places of their intersection with the drywall sheets.

The gypsum plasterboard sheets are attached to metal profiles by metal screws made of oxidized alloy. When screwing them in, the head should be slightly drowned, but it is not necessary to press hard because of the risk of damage to the drywall sheet.

Using the frame method is optimal for rooms in which additional thermal insulation is required. After the assembly of the frame is completed, glass wool, cork mats or other materials are placed between the racks, providing good insulation and sound insulation.

The specifics of drywall mounting without a frame

To attach the sheets in this way, special gypsum or cement glue is used. Before aligning the walls with drywall without a frame, you need to thoroughly prepare the surface. It should be cleaned from residues of substances that impede the manifestation of the bonding properties of the adhesive. A damp wall should be allowed to dry well. It is also necessary to prime the base if it is made of materials with strong absorbency or a smooth surface.

It should be remembered! With a combination of wet and “dry” plaster, the first to work on applying wet plaster to the required areas.

At the first stage, it is necessary to cut sheets of drywall with the given sizes. Optimum adhesion of the adhesive requires the presence of gaps on the floor side – 10 mm, ceiling – 5 mm. Mixing of glue should take place in strict accordance with the instructional material to a consistency resembling a thick curd mass. Before starting work on gluing drywall sheets, switch out switches and boxes for sockets a few centimeters.

For high-quality gluing of drywall sheets to the wall surface, so-called beacons should be affixed, i.e. drill holes into which you need to insert the dowels, and then screw the screws in level. This ensures an even arrangement of sheets vertically, since the caps of the screws will not allow the blade to go deep.

Glue is evenly applied to the back side of the canvas, special attention should be paid to door, window openings, ventilation ducts and so on. Plasterboard plates with glue applied must be attached to the wall and docked tightly, using a rubber mallet for this. Using the web level, align it vertically.

An important condition for reliable fastening is the uniform application of glue on a drywall sheet

Important! Alignment of walls with drywall without a framework can only be used in rooms with a ceiling height that does not exceed the height of drywall sheets, since the creation of horizontal joints with this method is unacceptable.

Using the frameless method requires certain skills when working, but using this method, space is saved (at least 3 cm) that the frame would occupy. However, editing using a profile nevertheless received the most popularity among alignment methods.

The final stage – putty

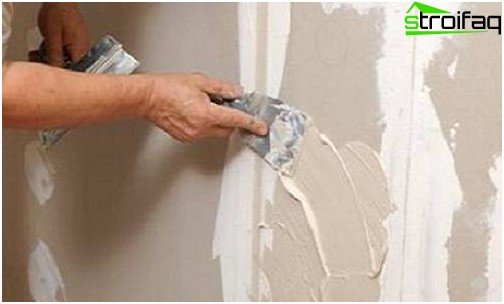

After installing the drywall sheets on the wall, it is necessary to check the canvas for flaws, the main of which are the protruding hats of the screws. They must be tightened to the end to ensure a perfectly flat surface..

At the final stage, it is important to align the seams between the sheets, to putty the places where the screws are screwed. To carry out these works, you need a reinforcing tape. When laying on the prepared joint, it should be pressed a little with a spatula into the first layer of putty, then covered with an additional layer.

Puttying joints between sheets of drywall – an essential component of the alignment process

After the putty has dried, you can begin to putty the plasterboard sheets directly..

Drywall putty finishing

Finishing putty can be omitted if tiles are glued to the walls. The end result of the work performed is a smooth surface that provides a huge scope for creative ideas of designers.

Of the modern features that allow you to visualize the alignment of walls with drywall – the video lesson occupies a leading position. Visual perception of the process features will allow you to perform this type of repair work yourself.