Successful operation of a roof covered with metal tile, its durability largely depend on the creation of an optimal temperature and humidity regime in the under-roof space. It is known that on the inner side of the roofing sometimes condensate forms, which, penetrating the insulation, can spoil its functional properties, and even penetrate into residential premises. In order to avoid such negative phenomena, waterproofing of the roof from a metal tile is carried out.

Content

- What is waterproofing of roofing for metal for??

- Types of waterproofing for metal roofing

- Preparatory work

- Installation of waterproofing step by step

What is waterproofing of roofing for metal for??

Waterproofing a metal roof is necessary for several reasons. The main one is the protection of the roof from contact with water, since water destroys building materials, especially metal ones. Even when installing a new ceiling, it is necessary to carry out waterproofing, since moisture means not only water, but also condensate, which forms when the temperature drops. Therefore, the main tasks of roofing waterproofing for metal are:

- exclusion of penetration of external moisture (melt and rain water);

- preventing the accumulation of condensate in the insulation;

- maintaining thermal insulation in good condition;

- preventing dust and dirt from entering the under-roof space.

Waterproofing is an important stage of a competent roofing device, which ensures reliable operation of the house for a long time.

Roof waterproofing under a metal tile will protect the roof from atmospheric moisture and prevent condensation from forming on the inside of the roofing

Types of waterproofing for metal roofing

Materials for waterproofing are different and they are selected depending on the needs. For example, an inexpensive film may be suitable for temporary coverage, but for membrane protection, membrane waterproofing should be purchased. How do they differ?

The usual film for waterproofing consists of a base layer and polyethylene. It protects only internal ceilings and is most often used only as a temporary measure (for example, during repairs) to prevent rainfall from entering the house. Accordingly, the price of this type of material is very low..

Materials for waterproofing are different and they are selected depending on the needs

If you need to install waterproofing once for many years, you should purchase a more expensive option – membrane waterproofing, which is characterized by practicality and durability. It consists of reinforced and absorbent layers that perfectly complement each other. The reinforced layer perfectly protects the surface from precipitation, and the absorbent layer, accordingly, absorbs moisture, preventing the formation of condensation and mold. Obviously, such material will have to spend a lot of money, but this will avoid problems with the roof in the future.

In roofs with cold attics for waterproofing under a metal tile, as a rule, glassine and roofing material are used. They provide good protection against wind and moisture, but if they are exposed to more tangible effects, they have a short service life. For a mansard roof, materials of a higher quality should be selected, such as, for example, film waterproofing based on polyethylene.

The film for waterproofing under the metal tile is of three types:

- classical (has double-loop isolation);

- superdiffusive membrane (with single-loop isolation, increasing the service life of the roof insulation);

- anti-condensation (has double-circuit ventilation, fleecy material that absorbs moisture).

Preparatory work

Before laying waterproofing material, it is necessary to correctly carry out preparatory roofing:

- the installation of the rafter system in accordance with the calculations made during the design of the roof. This work is recommended to be done in dry weather;

- laying the cornice board in pre-prepared grooves on the rafters and attaching the frontal board to the end of the rafter legs. These two elements will give the construction additional rigidity;

- the location of the hooks of the gutter under the drainage system.

Possible ways of installing waterproofing

Waterproofing under a metal tile is mounted in one of two ways:

- By rolling strips of film parallel to the cornice. With this method, the film is mounted with special sagging to the crate. The overlap of the strips should be at least 10 centimeters. And in order to provide ventilation between the film and the metal tile, the film is fixed by means of a super-railing counter-lattice.

- By laying the film perpendicular to the cornice. At the same time, the waterproofing material is placed on the finished crate and attached to the interference fit. And in this case, the overlap between the stripes of the film should be more than 10 centimeters.

Installation of waterproofing step by step

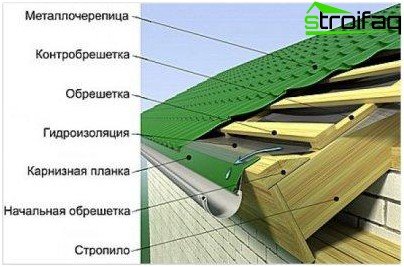

The waterproofing under the metal tile is laid in such a way that air flows pass unhindered from the eaves of the roof to the roof ridge and freely pass through the ventilation holes installed at the highest points of the roof and through the ridge seals.

The film is laid in horizontal stripes from the cornice to the roofing ridge with an overlap (15 cm) and fixed on rafters or logs

The film is laid in horizontal stripes from the cornice to the roofing ridge with an overlap (15 cm) and mounted on rafters or logs using a construction stapler or using stainless steel nails with a flat hat. Adhesive tape is used to isolate overlap sites. It is necessary to ensure that overlapping places fall on wooden structures. In addition, when laying the film, it is necessary to leave a sag of 2 cm between the rafters. This is done in order to avoid excessive tension or tearing of the film during sudden temperature changes..

It is not allowed to confuse the sides of the film. It is laid with the bright side of the edge tape to the roofing..

You need to know! There is a rule: as the film is rolled, so it is laid, it cannot be turned over, otherwise the waterproofing characteristics of the material are lost.

When using a classic or anti-condensation film, it is necessary to provide double-circuit ventilation, so in this case the height of the rafters should exceed the thickness of the insulation by 3-5 centimeters. If this condition is not met, then the distance blocks of 3×5 centimeters are clogged. This will create a ventilation space between the insulating material and the waterproofing..

Do not floor the film directly on the formwork or other floorings, as well as contact with the insulation. If the hydrobarrier is laid on the roof being repaired, on which there is a formwork or any other flooring, then logs with a section of 2×5 centimeters are laid on the roof slope. The distance between them should be from 1.2 meters or more.

It looks like a multilayer tin roof cake

When the insulating film is in contact with the flooring, it loses its waterproofing properties, so under the roof slope it is necessary to provide a gap of 5 centimeters, and also take into account the requirements of air circulation when fixing the edges of the material along the bottom of the roof. On the ridge, the ventilation clearance should be at least 5 centimeters. If the design is equipped with a lower groove, the waterproofing film should reach it with an edge, if it is absent, it is desirable to perform the lower edge of the film, combining it with a roof groove. All openings for the circulation of air currents are designed so that biological organisms – birds, insects – cannot penetrate through them..

To attach the waterproofing layer to the roofing elements, rubber adhesive tape is used. At the junction of the slopes, the overlap of the film should be 15-20 centimeters. At the exit sections of the furnace and ventilation pipes, the film is laid on the walls of these elements with an overlap of 5 cm.

The only waterproofing material that does not need a gap over the insulation is the new progressive superdiffusion membrane. It can be rolled right on the rafters. If the thickness of the rafters is greater than the thickness of the insulation, then when rolling the membranes they surround the rafters, repeating their profile.

In areas where there are attic windows, a waterproofing film is attached, guided by the specific design of the window, since each manufacturer of attic windows provides its own solution for attaching waterproofing to their own products.

After completing the installation of the waterproofing layer, you can proceed to the next stage of the roof device. Correctly completed installation of waterproofing is the key to the reliability of the structure to the same extent as the roofing itself.