Bathroom Waterproofing Guide

The specifics of the operation of the bathroom dictates the need to optimize waterproofing characteristics. In a room intended for hygienic procedures, a high level of humidity. Condensate settling on surfaces contributes to the destruction of building materials. Steam penetrating walls adjacent to the bathroom can ruin the finish. Waterproofing of the bathroom is also necessary in order to avoid the bay living below the neighbors in the event of emergency leaks. Summing up the arguments in favor of waterproofing, it is not difficult to conclude that these measures are much more economical than the cost of restoring someone else’s and personal property damaged by steam and water.

Content

- We plan to isolate

- Range of waterproofing materials

- Pros and cons of pasting materials

- Features of coating waterproofing

For the application of a layer that protects against the effects of condensation and water, the industry offers a wide range of products. There are a number of methods, the implementation of which is available only to experienced professionals equipped with special equipment. However, a perfect waterproofing can be done by any owner who does not have the skills of a repairman. You just need to select the right material, decide on the front of the work, study the execution technology, be patient and have the necessary tools.

Waterproofing the bathroom will help to save building materials, decoration, eliminate unpleasant situations with emergency flooding below the apartments

We plan to isolate

The preliminary stage of any work that requires expenses for the purchase of material should be planning. For this, you do not need to draw up projects, just a scheme with the exact dimensions of the bathroom. Clearly calculated area for processing will minimize costs by eliminating the acquisition of surplus.

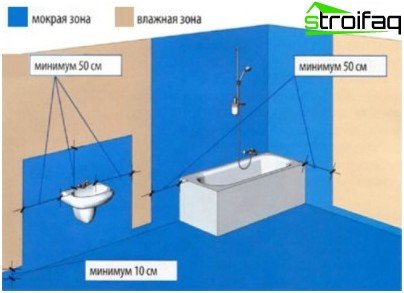

There is no doubt that the plane of the floor in the bathroom must be protected with an appropriate layer. If it is intended to lay the waterproofing material only on the floor, it is desirable that the lower 20 cm of the walls are also protected from moisture penetration by the same layer. Waterproofing in such cases resembles a kind of capacity that prevents sewage from entering the overlap area and to the bathrooms of the neighbors below.

If the owner of the apartment is concerned about the safety of the decoration of the walls adjacent to the hygienic room, the planes of the combined structures should also be processed. Waterproofing is also applied to the surface of the walls, near which showers and other plumbing equipment are installed.

Bathroom areas in need of insulation

Range of waterproofing materials

The difference in the methods of applying a layer that prevents the penetration of moisture, predetermined the division of the entire range of waterproofing on the gluing materials and on the now more popular coating compositions. Pasting or coating technology, choose, focusing on the preferred time for the owner of the premises to complete the work and the characteristics of the surface intended for processing.

Pros and cons of pasting materials

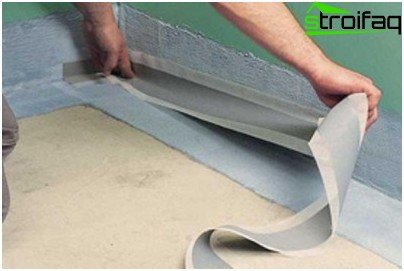

The most famous, tested method of waterproofing bathrooms was the application of rolled materials on the surface, the main component of which is bitumen. The rolled products supplied in the market today are modified by the introduction of polymer components, reinforced with fiberglass or other synthetic fabric. Among materials with a reinforcing base there are self-adhesive and weldable varieties. The technology of laying a waterproofing layer deposited on the surface is too complicated for a beginner and impossible without the use of a special burner. Therefore, inexperienced performers who prefer to save time and facilitate the production of work prefer glued options.

Recognized finishers and builders positive qualities of roll waterproofing are considered to be the ease of applying a self-adhesive insulation layer, the reduction of technological time. The waterproofing of the floor in the bathroom, made with the help of rolled materials, does not require waiting for the surface to harden, so that you can start decorating without delay: laying tiles, linoleum, porcelain. A significant plus is a clear fixation of adhesive modifications. They do not shift and do not deteriorate from the movement of people on a laid surface.

Bitumen-based roll materials for waterproofing rooms with high humidity

The negative sides of the gluing roll waterproofing:

- the need for preliminary leveling of the surface, since unevenness exceeding 2 mm is not permissible;

- the base intended for processing must be dried;

- the presence of a sharp toxic smell of bitumen, not “weathering” for a long period.

If, focusing on the speed of execution, the owner of the premises with a level surface still chose the gluing method, it is recommended to prefer self-adhesive options for waterproofing materials.

Features of coating waterproofing

Unpretentious universal coating compositions do not require careful preparation of surfaces before application, since to some extent they themselves function as a leveling layer. For those who want not to waste time on preliminary preparation, coating waterproofing is the best choice. This category of materials is more expensive than gluing analogs, but, given the lack of the need to buy leveling mixtures, it is quite acceptable and even economical.

Coating compositions are presented:

- bitumen-polymer mastics with a base of oxidized bitumen and the inclusion of an organic solvent;

- bitumen-rubber mastics enriched with synthetic fillers increasing elasticity;

- cement-polymer mastics, which are a mixture of cement with mineral additives.

You should know that if the floor waterproofing in the bathroom was carried out using mastics with a bituminous main component, subsequent filling of the screed is necessary. Such a scheme will completely prevent the penetration of moisture. But in order to prevent shrinkage cracks after screed, polypropylene fiber will need to be added to the composition. This modifying component will also strengthen the concrete base..

Waterproofing the bathroom with plaster

Lubricants are distinguished by excellent adhesion to the treated surface. The presence of plasticizing inclusions contributes to the improvement of work with any rigid base. Priorities for processing concrete structures with mastics are determined by the maximum penetration of the compounds into the concrete structure and the formation of new stronger crystalline bonds. Crystalline formations created using mastic components interfere with water, but let air through.

Material quantity calculation

After the future contractor has decided on the front of work, figured out which planes he will process, and selected the material, it will be necessary to calculate the required amount of coating paste, rolled waterproofing, or both materials if they are used together. To calculate the need for material, there is an elementary formula – the area of the processed surface is divided by a kind of coefficient equal to 1.5. Round the result should be up. For applying the impregnation or laying the layer only on the floor, the main parameter to be divided will be the floor area. Do not forget that 20 cm of walls around the perimeter is also desirable to isolate. By analogy, the need for self-adhesive material for walls or segments of vertical surfaces is calculated.

Technology of a waterproofing of a bathroom

Preparatory phase of work

Regardless of the choice of material and method of waterproofing, the starting stage should be the preparation of the surface for subsequent processing. All planes planned for application of materials must be cleaned of dirt, worn coatings, traces of oil products and grease-containing compounds.

In order for the waterproofing of the bathroom with your own hands to be effective, you need to pay attention to the following nuances:

- Before fixing the roll layer on the wall or laying it on the floor, alignment should be carried out, these measures are not needed before applying the mastic;

- it is necessary to grind the concrete surface, remove a weak layer, the so-called “concrete milk”, carry out a breakdown of damage and cracks, repair them using special compounds;

- concrete is moistened before waterproofing, but excess water is not allowed on the floor surface.

In order to form the maximum insulating effect, it is recommended to conduct additional insulation of the junction of structural components and seams between the elements. For this, a seam is made in the seam with a depth of not more than 3 cm, which must be filled with a special solution. A more affordable way is pasting butt joints with insulating tape.

The adjoining areas of the structural elements of the bathroom are treated with special adhesive tape

Essential recommendation: Before applying any waterproofing material, a rough surface should be primed to optimize adhesion. Perfectly paired with an insulating coating material will be a composition for priming a similar class. Those who want to make the insulation of the bathroom using rolled self-adhesive materials should prefer compounds compatible with the base, you can simply cover the surface with waterproofing paint. The soil must be dry before further work..

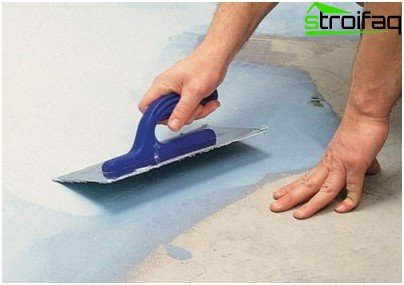

Coating waterproofing

Among the coating materials on the market there are prepared compositions and dry mixes for the preparation of which you need to carefully study the manufacturer’s instructions and follow all the points indicated in the instruction. A ready-made or self-made homogeneous mixture is applied with a flat brush, a special roller or a construction spatula, evenly distributing the coating material over the surface. If the manufacturer advises repeated application, each of the subsequent layers is sent “to the cross” to the previous one. Between the application of the layers, the interval specified by the manufacturer, required for complete hardening, must be observed. At least a day should pass after treatment with coating materials, after which it will already be possible to proceed to facing.

Self-adhesive insulation and other methods

All work consists in cutting and fixing the waterproofing material. The shape of the layer laid on the floor should resemble a trough. The final stage – processing joints with a silicone-based sealant.

The cheapest simple scheme for waterproofing the bathroom – staining with a special composition

Owners, puzzled by the question “how to make waterproofing in the bathroom as cheap as possible,” the repairmen advise to simply cover the surfaces with a waterproofing paint composition that prevents the penetration of vapors and moisture. The cast option is not advised, it is effective, but difficult for independent execution. The backfill insulation layer will be too powerful and not particularly effective..

There are not too many ways to improve the waterproofing characteristics of the bathroom, available for independent execution, but enough for a choice. There are tangible differences between them. What is more important for the owner: speed or cost? He will decide on his own, and after getting acquainted with the specifics of the work, it will be much easier to make a reasonable decision.