Drywall partitions

Currently, drywall partitions have gained wide popularity and won the love of both builders and ordinary consumers. The fact is that such a design has many advantages. Firstly, the finished partition has a smooth surface, which allows immediately after its installation to use various finishing options: paint, wallpaper or other materials. Secondly, drywall sheets have good performance characteristics, in particular, they are vapor permeable. This allows them to create the most optimal microclimate in the living room. In addition, drywall partitions are safe in case of fire, as they are quite fireproof. The ability to mount partitions of almost any configuration is also an undoubted advantage of this material.

Content

- Drywall sheet – perfect metal frame cladding

- The basis of the interior design is a metal frame

- Guiding profiles (PN) for plasterboard partitions

- Rack profiles

- Corner profiles for partition joints

The design of such a partition may be different. So, the sheathing of the metal frame can be single-layer or two-layer. The thickness of the profiles used to create the frame can also be different..

Speaking about the construction of drywall partitions, their main elements should be determined. These include directly gypsum plasterboard sheets, a metal frame made of profiles (rack, rail, corner) and insulation materials.

Drywall sheet – perfect metal frame cladding

Gypsum plasterboards (GKL) are often called gypsum panels or dry plaster. Their main purpose is the manufacture of suspended ceilings, various types of partitions and wall cladding.

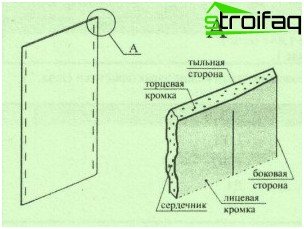

The structure of this finishing material is quite simple: it consists of a core made of gypsum and cardboard for cladding. The core is most often made of gypsum brand G-4, which is characterized by all the properties necessary for construction and finishing work. GCR, made on the basis of this gypsum, promotes the absorption of excess moisture from the air, and if it is lacking, its release. Thus, gypsum board can rightfully be considered a “breathing” material..

GKL structure

The finished gypsum core is covered with cardboard. High-quality adhesion of these two materials is carried out using special adhesive additives. Cardboard is a kind of drywall sheet frame, which, among other things, is also a working surface for decoration.

Today, there are several different modifications of GCR, each of which meets the necessary requirements in certain operating conditions. So we can distinguish:

- GKLV. This is drywall used in rooms with a high degree of humidity. Such sheets are subject to special treatment with various waterproofing compounds and antiseptics..

- GKLO is ideally suited for those rooms where the probability of fire is rather high. In the manufacture of such drywall, certain additives are used that increase fire resistance.

- GKP – combined drywall sheets.

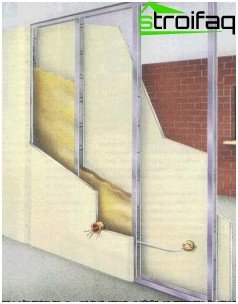

The basis of the interior design is a metal frame

The basis of the drywall partition is its metal frame. Its installation is carried out from several types of profiles, each of which differs in certain functional loads. For the manufacture of profiles, as a rule, steel tape is used. Its thickness can vary from 0.55 mm to 0.8 mm. Cold Rolled Profiles.

Plasterboard Partition Metal Frame

Protection of profiles from negative environmental influences provides their galvanization. A normal air environment contributes to the formation of zinc carbonate on the surface of the profile. A layer of zinc protects the profile from the spread of the oxidation process. The effectiveness of such a protective coating is determined by a fairly strong adhesion of zinc and steel surface.

Undoubtedly, the metal frame must be strong enough to withstand not only its own weight, but also the weight of drywall sheets, future decoration materials and possible hanging elements, such as watches or paintings. To ensure a high degree of strength of the profiles used, stiffening ribs taking place on the profile plane help. Outwardly, they resemble corrugations along.

Profiles can be:

- rack-mount;

- guides;

- angular.

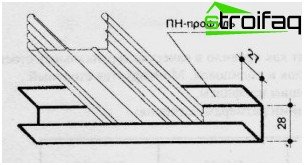

Guiding profiles (PN) for plasterboard partitions

Guide profiles are one of the main elements of the partition frame. They have a special section in the form of a channel. The main purpose of such profiles is to create a guide base for rack-mount counterparts. In addition, the guide profiles can play the role of jumpers located between the rack profiles. This need may arise, for example, when installing door frames in a partition.

Each guide profile has special holes for dowels, with which the frame is attached to the base. Additional holes may be drilled if desired..

Guide profile (PN) for plasterboard partition

Rack profiles

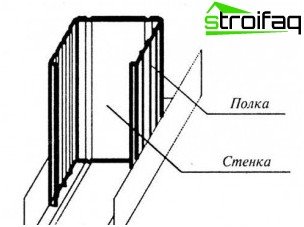

In addition to guide profiles, the installation of drywall partitions involves the presence of rack profiles (PS), which also have a cross-section similar to a channel. They are used to create vertically arranged racks of a metal frame of a drywall partition. These racks are designed to securely fasten drywall sheets on them..

To the central part of the rack profile, which is called the “back”, at an angle of 90? bends two shelves. Their width is 0.5 cm. It is worth noting that it is nominal, since its real width is approximately 0.48 cm. This profile configuration allows for a sufficiently reliable and strong adhesion of two profiles – guide and rack. The indicated width of the shelves contributes to the precise penetration of the screw into the hole. This is especially important when facing the frame in two layers of drywall.

In addition, the shelves of the rack profile are distinguished by the presence of longitudinal grooves, usually in the amount of three pieces. The middle groove is a kind of indicator of the place where the sheets of drywall are joined. The side grooves center the screws used. When installing a metal partition, it may be necessary to lay certain engineering communications. For these purposes, there are special holes in the back of the profile. As a rule, they are paired, and their diameter is about 33 mm. Installation of rack profiles is carried out directly in the guide profiles. For their high-quality connection, screws are most often used..

Rack profile for metal frame

Corner profiles for partition joints

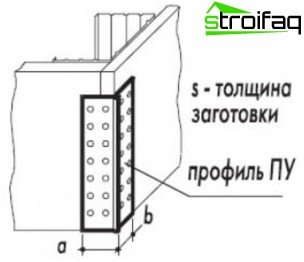

Corner joints during the installation of the partition are quite vulnerable places. For their device, plasterboard sheets with a straight edge are most often used. However, this solution has one drawback – there is an increase in the likelihood that mechanical damage to the partition will occur during its direct operation. In order to avoid such undesirable consequences, it is customary to use corner profiles (PU).

The advantage of the angular profile is that it fits snugly enough to a 90? Partition angle. The adhesion between the drywall sheet and the metal profile is carried out using putty, which fills the holes in the profile shelf. If the surface made of plasterboard sheets is curved, then arched profiles are used, the bending radius of which can vary.

Plasterboard partition angle profile

Plasterboard partition insulation

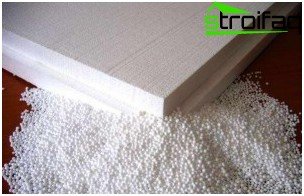

Often, soundproofing and heat insulation are provided for in drywall partitions. Expanded polystyrene is the most common insulation material for this, but mineral wool can be an alternative..

The particular popularity of expanded polystyrene is due to its performance. The fact is that it has a stable structure in a wide temperature range. It is not adversely affected by various chemicals. In addition, polystyrene foam does not create a favorable environment for the growth of bacteria and mold fungi.

Expanded polystyrene for sound and heat insulation of plasterboard partitions

Thus, the partition of plasterboard sheets includes a number of structural elements, each of which has its own purpose. Knowing their features allows you to quite competently approach the issue of arranging the partition, to avoid the most common mistakes during its installation and to obtain a high-quality result.