The organization of a ventilation system that supplies fresh air to the house and displays the spent mass outside is a necessity dictated by the provision of standard sanitary and hygiene standards. Supply and exhaust ventilation device is a strict requirement in the presence of gas heating. A system with natural air circulation is being built in small one-story houses. Devices for the implementation of air exhaust must be installed in bathrooms, saunas, kitchens, fireplace rooms, if any. Regardless of the method of air exchange, mainly channel-type systems are constructed using ventilation ducts, the characteristics of which are worth familiarizing with.

Content

- The specifics of the construction of ducts

- What is better plastic or metal?

- Technical Comparison

- Hard and corrugated channels

- Assessment from the point of view of the installer

The specifics of the construction of ducts

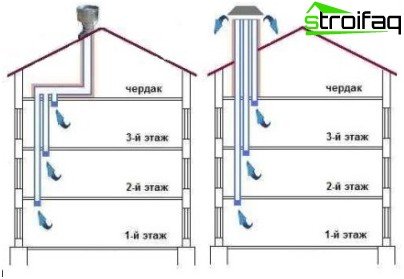

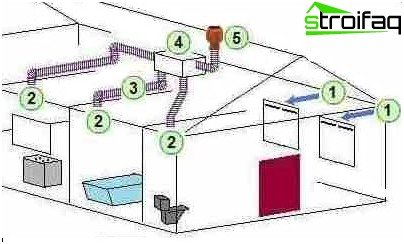

If the ventilation system is installed during the construction of the building, they are usually laid in the wall so as not to spoil the interiors with not-so-attractive communications. Best of all, if the ducts are placed vertically next to the chimneys (no closer than 10 cm), which will contribute to increased traction. Optimally, if each room has a separate duct, and all of them are combined into one outlet channel. Other wiring schemes are allowed if the premises are in different parts of the cottage.

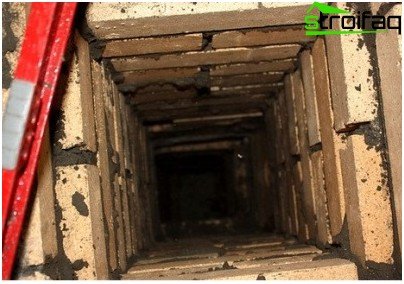

If the device of the air exchange system is produced during the construction process, ventilation ducts are laid in the walls or in the mines constructed for their installation

Attention. The intersection of ducts with sewer, gas, water pipelines and building codes is prohibited. Sewer piping must not be laid in ventilation shafts.

The channels can be laid out with a brick or mounted using ready-made pipes for ventilation. The latter method is less time-consuming, it is easier to implement it yourself. Most often, galvanized steel or aluminum pipes were used to organize the ducts. Metal products are now installed in offices, public buildings, and in industrial premises characterized by a high degree of explosion hazard. However, with the introduction of polymer products in various areas of construction, plastic pipes for ventilation began to actively displace metal analogues.

Two options for the installation of air ducts: on the left – all air ducts are combined into a common system with one outlet pipe, on the right for each room has its own air duct

What is better plastic or metal?

Before starting to compare products from materials with different technical characteristics, we will study the list of requirements for air ducts. After all, the function of galvanized metal products and PVC pipes for ventilation must fulfill one.

Technical Comparison

General requirements for ventilation ducts:

- Ensuring impeccable tightness.

- Creating conditions for the free passage of a stream of a specific volume with a given project speed.

- Compliance with sanitary standards on the composition of products and the level of noise generated.

- Resistance to burning.

- Maximum combination with room design.

- High insulation performance.

To form tight joints, both plastic ducts for ventilation and metal products are equipped with special flange elements. That is, you can build a system of any complexity from both options. PVC products and metal pipes are available in various shapes and sizes. This means that there will be no complications in choosing suitable pipes in both cases. But in terms of insulation characteristics, innovative material is significantly ahead of metal, which requires mandatory insulation in the passage through the roof.

In the area of passage through the roof structure, galvanized ducts must be insulated to prevent the formation of condensation, which corrodes metal, plastic is not afraid of moisture

Non-combustible galvanized pipes for ventilation are indispensable for the construction of an air exchange system in hazardous workshops with the risk of fire. However, for the arrangement of housing with standard operating conditions, they are not required, but bulky tin ducts can completely spoil the interior picture. Moreover, in the case of turbulence in the metal channel, the noise negative amplifies, reflecting off the walls, which does not happen in plastic ducts.

Tip. To avoid “twists” with a characteristic sound negative, it is advisable to lay corrugated pipes for ventilation and rigid channels with a minimum number of turns. Do you need to avoid angles of 90? and sharp transitions from one pipe diameter to another.

Welded flanges for galvanized steel pipes are necessary for making tight joints, for making turns with a certain degree of flange model, for wiring and changing to another diameter

By the sum of operational advantages, plastic is ahead of metal; the only drawback of PVC is insufficient fire resistance. If the exhaust pipe for ventilation is installed next to the chimney, it is better to refuse polymer products.

Hard and corrugated channels

Depending on the complexity of the system being constructed, rigid and flexible air ducts are used in the process of its construction. With rigid elements, everything is clear, they are in both variations with a round and square section. The round ones are more beautiful and more compact, they are mainly used for the construction of ventilation in a country house.

Flexible pipes are needed if in a small area the channel needs to be turned several times to connect to the main line.

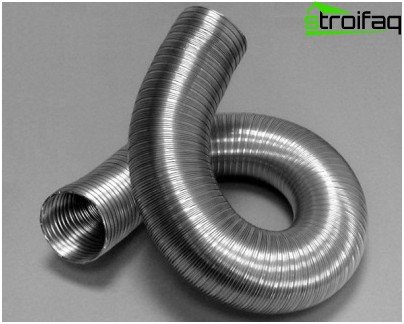

- Flexible metal ducts for the ventilation system are made of multilayer aluminum foil with a corrugated structure. You can bend them at any angle, but you need to remember that the inner surface, which is not distinguished by smoothness, creates additional aerodynamic drag.

The use of a metal flexible duct allows you to quickly arrange the system and use a minimum number of flanges

- Flexible corrugated plastic pipe for ventilation is made of polyester and aluminum foil. Its multilayer structure is reinforced with steel wire, laying coils between the layers. PVC products are now being produced with improved heat-insulating and sound-absorbing qualities. They are used for laying ventilation ducts in housing.

Corrugated plastic pipes – the most common option for ventilation in rural cottages: a minimum of connections and fixtures, the maximum pace of construction

Corrugated products are suitable for laying ventilation ducts with low pressure (800-5000 Pa) and low air velocity (30 m / s).

Assessment from the point of view of the installer

Be sure to include any ventilation ducts: their installation is inevitable and not easy, but you can choose a material that can reduce labor costs.

- Plastic is lighter. This quality is a priority during the construction process, during transportation, and during operation.

- For fastening the channels, devices capable of holding a large load will not be required. Sagging channels should not exceed 4%.

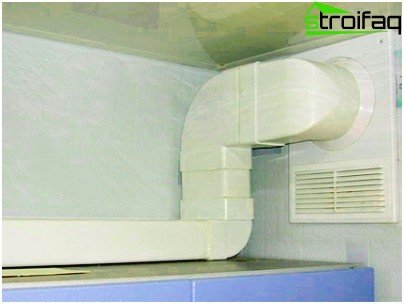

- PVC ducts for ventilation with your own hands can be freely cut to the size necessary for laying a complex configuration. Working with metal is much more difficult.

It is easier to build a plastic ventilation duct with your own hands, the pipes are easy to cut, so you can make ventilation of any complexity, there are special elements for making corners and joints, a smooth surface does not create obstacles to air flow, they practically do not need to be cleaned

Are sewer pipes suitable??

For the laying of air ducts, special plastic products with a diameter of 120 mm are produced. The structure and composition of the material are similar to sewer pipes, but the cost is almost five times higher and the diameter is 110 mm. At forums of craftsmen, the question of whether ventilation from sewer pipes can be built is actively discussed. Is it possible, for example, to connect a corrugation made of plastic with a diameter of 120 mm to an exhaust pipe made from a sewer pipe?

Compulsory ventilation scheme: 1) ventilation grilles on the windows for fresh air intake, 2) exhaust openings for exhausting the exhaust air mass, 3) flexible air ducts, 4) control equipment, 5) output device with a diameter exceeding the size of the air ducts

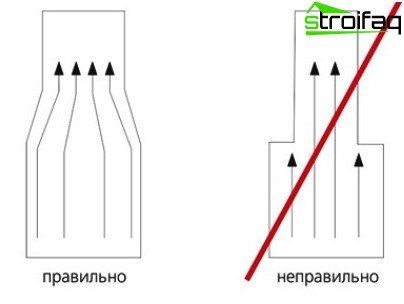

According to building rules, the output device should be wider. However, many believe that a narrowed by 10 mm passage will not affect the functionality of the system. The main thing, in their opinion, is that the connection be airtight, for which the joint is tightened with double-sided tape and other insulating materials. In general, it is not recommended to switch to a different diameter when constructing a ventilation network. And in the place of air exhaust the narrowed passage will hamper the movement. But if it does not work out otherwise, the transition should be smooth without “steps”.

The connection of pipes into a single channel should be smooth without sharp transitions from one diameter to another and “steps”. Left – right, right – wrong.

It is no accident that consumers are switching so actively to plastic products. They are lighter, cheaper, ahead of obsolete metal options in technological, aesthetic, and operational parameters. A weighty addition to the pluses is a rare departure, because on the smooth surface of the plastic with antistatic properties, the sediment clogging the duct does not accumulate.