Air recuperator – what is

Everyone knows that in order to create a healthy indoor climate, ventilation is necessary. Clean air must enter the room from the street, but at the same time, the same amount of air is removed from the room. In winter, together with the outflow of “exhaust” air, valuable and so expensive heat is now irrevocably leaving the room, and in summer, when the air conditioners are working in the room, the supply hot air only complicates their work. So, in order to literally not let this money go down the drain, an air recuperator was invented.

Content

- What is a recuperator??

- Device Data Classification

- Rotary type recuperator

- Plate type recuperator

- Forced-air and exhaust installation with a recuperator

- Functions, Work, Tasks

- DIY recuperator how to calculate efficiency

What is a recuperator??

The word “recuperator” comes from the Latin “recuperatio”, which means the return or return. In our case, this is a heat exchanger that returns heat in winter, leaking from a room with exhaust air, and in the summer prevents heat from entering the supply air.

So how is the heat recuperator arranged, and what is the principle of its operation? The schematic diagram of the recuperator is quite simple and is a double-walled heat exchanger, in which, without mixing, there are two air flows – exhaust and supply. Due to the temperature difference of the air flows, they exchange thermal energy with each other, that is, cold air is heated, and warm air is cooled. In addition, when cooling warm air, moisture is removed from it due to condensation on the walls of the heat exchanger.

Recovery is, in fact, a method of reducing losses through the ventilation system, that is, energy-saving technology. With the help of heat recovery, more than 70% of the waste heat can be saved. Energy is reused in one process! There are recuperators of various capacities and designs.

Device Data Classification

- According to the scheme of movement of coolants (straight-through, counterflow)

- By design (tubular, ribbed, lamellar, etc.)

- By appointment (for heating air, liquids, gases)

Rotary type recuperator

The rotary recuperator is characterized by excellent efficiency, the main disadvantage is the large dimensions

It is represented by a short cylinder filled with densely packed longitudinally arranged layers of corrugated steel. Such a rotor is located in the direction of the axis of the flow-exhaust device. The recuperator drum rotates, first passing exhaust warm air through itself, then supplying cold air. Alternating heating and cooling of the plates takes place, heat is transferred to the incoming cold air. Rotary recuperators are highly efficient, but they are quite bulky. For the proper organization of the supply and exhaust system, you need a spacious ventilation chamber.

Plate type recuperator

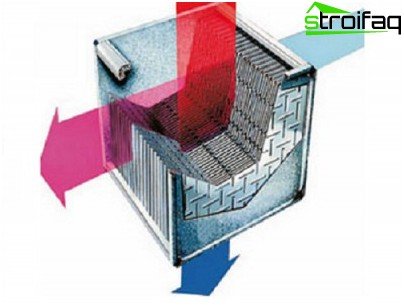

The main disadvantage of the plate heat exchanger is the frequent freezing of the supply side of the outdoor plates in the winter

It is represented by a cassette in which the supply and exhaust air passage channels are separated by plates of galvanized steel sheets. The flows do not mix, but heat transfer is inevitable due to the fact that the plates are simultaneously cooled and heated from different sides.

A plate air recuperator (also called cross-precision) is quite common due to its low cost and compact design. But there is one feature – there is a high likelihood of freezing of the device from the exhaust side, if the outdoor temperature is low enough, due to the formation of condensate in the exhaust ducts.

The device and principle of operation of the plate heat exchanger

If we evaluate the effectiveness of plate heat exchangers, then the efficiency of such devices is about 60%. Another important feature is a very simple device of the heat exchanger (without rubbing and moving parts), in this device does not use any elements consuming electricity.

A plate heat exchanger, despite some drawbacks, namely: frequent freezing of the heat exchanger in the cold season, a design feature of the mandatory intersection of the pipes of both air ducts in the heat exchanger, which can be difficult to implement, is most common for the supply and exhaust installation in homes, apartments and garages. Freezing of the heat exchanger is done by periodically turning on the supply fan or bypass valve.

Along with factory recuperators, the use of homemade units is widespread, because making an air recuperator with your own hands is not so difficult. Consider a household recuperator in operation.

As you can see, a homemade recuperator can be quite effective.

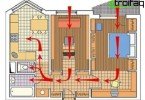

Forced-air and exhaust installation with a recuperator

Let’s consider the ways of arrangement garage ventilation systems. Garage ventilation can be natural, combined and mechanical.

- Natural ventilation – this is when a hole is made in the garage wall for air to pass through, and an air duct is inserted into the ceiling to divert the “exhaust” air.

- With combined ventilation, the inflow is left natural, and the exhaust pipe is supplemented with a fan operating from the mains for forced air exchange.

- Mechanical ventilation is the most expensive, but at the same time the most effective method of air exchange. Air outflow and air inflow are forced; a design with different modules for air inflow and outflow is possible.

The work of the mechanical system units is coordinated, the most expensive module is a device that provides fresh air. The design of such a device requires a fan, filters, air heater. The recuperator introduces additional features into the design, which we examined above..

Functions, Work, Tasks

- Efficient heat transfer.

- Condensate removal.

- High performance.

- Noiselessness

The optimum temperature for keeping the car in the cold season is +5 degrees, and the use of such a supply and exhaust system with a recuperator often replaces the use of a heating system.

DIY recuperator

If you are planning to make a plate heat exchanger yourself, then you need 4m2 of galvanized sheet, it should be cut into 20 × 30cm plates and put them in a stack. The plates should be perfectly even, so if galvanizing is used, it will be more convenient to cut a stack of three sheets with a grinder than to use scissors for metal. To create a remote gap between the plates, you can stick to them a framework of strips of technical plugs (thickness 2mm). The gaps between the plates must be at least 4 mm so that there is not too much resistance to air flow. It is important to choose the correct cross-section of the recuperator – the air flow rate should be equal to or slightly more than 1 m / s. After laying the entire stack, fill the gap with a neutral sealant.

After the sealant has dried, the plates should be put into the case (any tin box of a suitable size). The housing is made of tin, holes are made in it, into which plastic flanges are inserted, the diameter of which must correspond to the diameter of the air ducts. All slots are sealed with silicone sealant. The box is made of fiberboard or plywood 18 mm thick, all walls are insulated with mineral wool. The total area of the plates will be 3.3m2 with a capacity of 150m3 / h; the recuperator assembled in this way should have an efficiency of 50-60%. In winter, when the outside air temperature is below -10 ° C, plate heat exchangers can freeze, therefore, for periodic defrosting, a pressure change sensor must be installed in their warm part. During freezing, the supply air will pass through the bypass, and the heat exchanger will begin to defrost warmed by the exhaust air.

A modern home ventilation system is a must. After all, only traditional ventilation ducts in the kitchen and in the bathroom can not maintain a healthy indoor climate. Modern finishing materials are most often “non-breathing”, technologies aimed at energy saving (the production of plastic windows, for example) make it possible to obtain an almost tight room. An additional forced-air and exhaust installation with a recuperator will help ensure normal air exchange and solve the problem of the development of fungi and mold, which is especially important for humid rooms with poor ventilation. Thus, a recuperator for an apartment, a private house, and even more so for a garage (excessive humidity in the garage inevitably leads to corrosion, and exhaust gases and fuel vapors in combination with “stale” air are harmful to human health) is an absolutely necessary device.