Basement decoration

Being a spectacular decorative element of the exterior, the basement of the house performs a very important function of protecting the lower part of the building from aggressive external environmental influences. The basement is the upper part of the foundation towering above the earth, taking on all the vagaries of the weather, from frost and snowfall to heat, torrential rains and floods..

Content

- What is the base trim for?

- Choosing the best material

- Natural stone lining technology

- Stage One: Foundation Preparation

- Stage two: stone basement

- Stage Three: Finishing the Finish

What is the base trim for?

In accordance with building codes, the height of the basement should not be lower than 50-70 cm, but often this structural element of the house is raised to 150 cm and higher, especially if basements, garages, and other rooms are equipped in the basement. Finishing the basement of the building solves the following tasks:

- Waterproofing the basement and basement from the effects of heavy rainfall, groundwater and floods. The waterproofing of the base provides optimal constant humidity both in the basement and throughout the house – one of the main conditions for a comfortable microclimate and durability of the whole structure.

- The thermal stability of the base smooths out sudden changes in the temperature of the environment, soil and the interior of the house both in the summer heat and in the winter cold. To ensure a healthy comfortable microclimate throughout the building, the temperature difference in the premises of the basement and the house should not exceed 2-3 ° C.

- A decorative element, thanks to which the house looks respectable and dignified, regardless of what materials it is built from.

Choosing the best material

After all engineering communications are brought into the house, you can start finishing facade works and start with finishing the basement. In most cases, finishing materials are chosen at the design stage, but everyone makes a choice between plaster, tile, siding and finally natural or artificial stone. Everyone wants the house to be beautiful, but, if possible, almost everyone is also eager to save. Plastering the base is still the most economical way to finish it. Only if we do not forget about the durability, water resistance and heat resistance – the main functions of finishing the base, it becomes clear that even the most modern technology of facade plaster “graphite under the stone” does not quite meet them.

Firstly, it’s expensive, and secondly, it needs periodic, every 3-5 years, updating and repair, requiring additional costs. The rest of the budget finishing materials have their pros and cons. Natural stone is an ideal material for facing the basement of any building: it practically does not absorb moisture, has low thermal conductivity and has practically no competitors in terms of durability. As for the price, if you use rare types of granite or marble for decoration, of course, such a basement will cost a lot. But there is also a decent budget alternative to expensive rocks – natural sandstone, limestone, buty and some others.

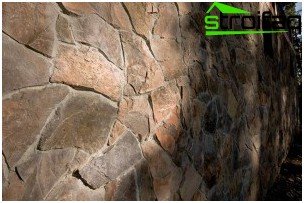

Thanks to the stone basement decoration, the house looks respectable and dignified, regardless of what materials it is built from.

Sandstone or limestone plates of irregular fragmentation shape, but of uniform thickness, with the help of which you can create different, not repeating patterns for finishing the base, are especially good for finishing facade work. A palette of colors and shades of sandstone and limestone from light gray and black to beige and terracotta red allows you to choose the finishing material for the basement to any color scheme of the house. Some types of natural stone, such as sandstone, are specifically burned in furnaces, increasing its strength. The result is beautiful natural material that can be used to clad not only plinths, but also external walls, garden paths, fireplaces, creating a harmonious architectural ensemble of the entire estate.

Important tip. When choosing a stone, sprinkle water on its surface and you will see what a saturated “wet” color it will acquire with scrupulous observance of the finishing technology.

Natural stone lining technology

Before finishing work, when the stone has already been selected and purchased, you must still purchase the following auxiliary materials:

- extruded polystyrene foam – an ideal non-combustible insulation;

- special mounting dowels;

- primer;

- special metal mesh;

- cement composition for grouting;

- lacquer for top coat.

Now you can proceed to facing the basement with a stone, alternately performing the following stages of work.

Stage One: Foundation Preparation

The surface of the base is plastered, and then the insulation plates – extruded polystyrene foam are fastened with special dowels

The surface of the base, whether it be brickwork, monolith or other material, should be plastered, smoothing out all the bumps. After the plaster completely hardens, it is necessary to attach insulation boards – extruded polystyrene foam to the flat surface of the base with the help of prepared special dowels.

Thus, a high stability of the basement of the building to the sharpest changes in ambient temperature is achieved. Then, a layer of acrylic quartz primer for outdoor work is applied to the surface of polystyrene foam boards and a special steel mesh is mounted on it. At this preparatory stage ends.

Stage two: stone basement

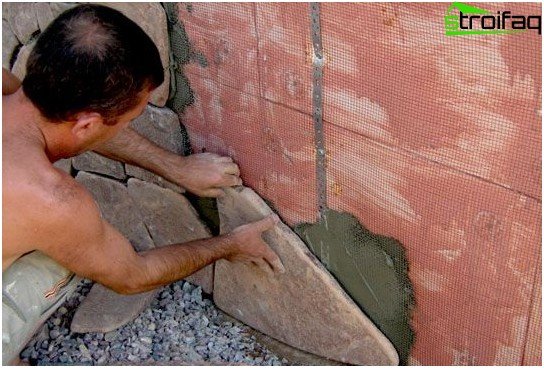

We spread the pattern – imitate the masonry

This is the most responsible, most difficult, but also the most creative stage. Usually, the master stacker pre-sorts the stone slabs in size, shade, thickness and even surface texture, and then, like an artist, with the help of glue, he puts out a mosaic pattern from them, trying to touch the stone with tools as little as possible, preserving the natural perfection of the noble material.

Stage Three: Finishing the Finish

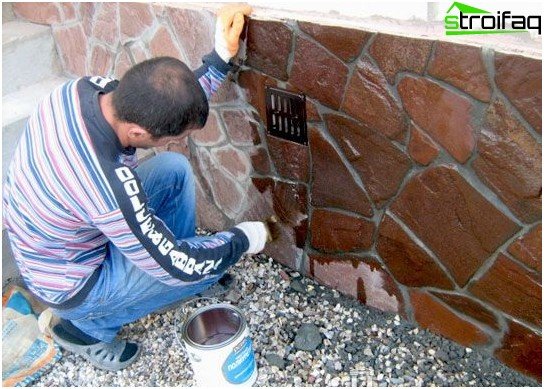

Now it remains to grout the joints with a special cement mortar, wash the coating, dry and apply a special varnish for the stone

As soon as the laying of the stone is completed, the finish of the basement already takes on a fairly solid appearance, but it still needs to be washed well from dust and traces of glue. You can use a washing vacuum cleaner or just a stream of water under pressure from a watering hose. Now it remains to carefully grout the seams with a cement-sand mixture of the corresponding shade and again wash the lined surface of the socle well. At the end of the last stage, it is advisable to apply several layers of special varnish on a well-dried surface of the cladding.

Application of varnish on a basement

In addition, thanks to the varnish coating, the color stone trim base becomes more saturated, such a finish provides dust-repellent properties to the coating and protects the surface from mechanical damage and other adverse external influences. The basement is finished, now you can start decorating the walls of the house.