Portable ground

Disabling current-carrying parts of a powerful electrical installation, a transformer or a fragment of a power transmission line does not guarantee full protection of people working on individual elements of electrical systems from damage. An area that is disconnected from the power supply may cause an unintended induced or high voltage. To exclude the impact on people of unforeseen factors, an additional protective measure is used – portable grounding, which does not allow voltage dangerous to humans to appear beyond the zone of its installation.

Content

- Portable grounding device

- Portable grounding systems for overhead lines

- Switchgear protection

- The list of requirements for protective systems

- Grounding requirements

The function of a portable grounding system is to reduce to zero the values of a voltage that is randomly directed or suddenly arises due to someone else’s error. In fact, this protective device causes a short circuit in a grounded or shorted area. In addition, after the protection is activated, the voltage source is automatically turned off. Excessive frivolity regarding the use of a portable grounding device, neglect of its installation, the use of low-quality products, violation of operating rules often led to disastrous consequences and even fatal injuries.

Portable Earthing – a means of collective protection against damage by accidentally directed, suddenly generated current

Portable grounding device

The portable grounding system consists of 3 main parts, these are:

- conductive component;

- contact part;

- an insulating element or several insulating elements.

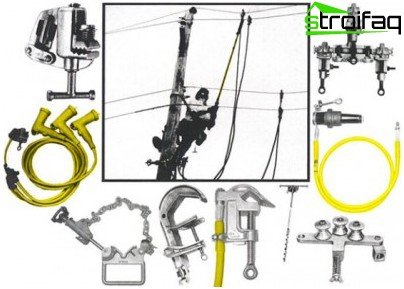

By design features, portable protective systems are divided into rodless, rod and rod with metal links.

Rodless design includes:

- a flexible wire as a conductive part;

- contact part, consisting of a clamp, phase clamps with fasteners;

- insulating part made of flexible control and supporting halyard.

The rod grounding portable device includes:

- conductive component made of flexible wire;

- contact phase clamps, clamps, tips;

- insulating rods made of dielectric material.

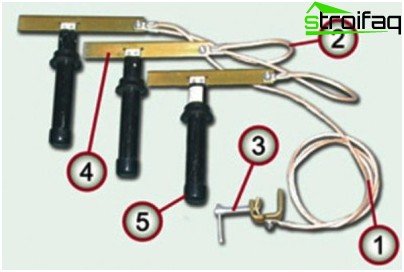

Bar grounding: 1. phase clamps, 2. rods, 3. shorting wire, 4. grounding wire, 5. clamps

The design of a portable grounding device, classified as a rod system with metal parts of the systems, consists of:

- a conductive rod with metal links having an electrical connection with a flexible wire;

- a contact clamp connected to a clamp with a metal link;

- insulating dielectric rod connected to the conductive component of the system, as well as to the halyards.

These collective protection systems produce three and single-phase. Three-phase portable devices with a single grounding conductor short-circuit and ground the three phases. Single-phase devices are used to protect personnel working in powerful electrical installations with voltages exceeding 110 kV in operating condition. This is justified by too large distances between phases, which is why protection systems are very long and heavy.

Portable Earthing with electrodynamic knives: 1. grounding wire, 2. shorting wire, 3. clamps, 4. knives, 5. dielectric rods

Portable grounding systems are used to protect people performing repair and installation work on overhead lines (OHL), transmitting electric current and in distribution electrical installations (RU).

Portable grounding systems for overhead lines

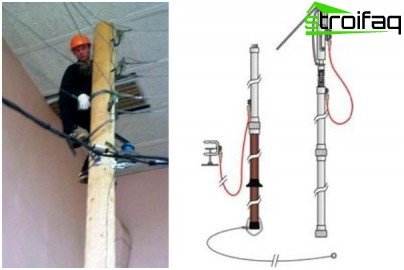

To ensure safety during repair and modernization work on overhead power lines, two types of single and three-phase portable grounding are mainly used.

- Devices equipped with an integral insulating rod. They are installed when working with lifts, towers, and also when using to climb to the place of work manholes and claws.

Portable earthing for safety on overhead lines

- Carrying earthing with a composite rod including conductive metal links. They are used if repair work on the high voltage power lines is carried out from the traverse. They are produced in a single-phase version, since a long bar in combination with metal links is too heavy. Single-phase devices create a minimum load on the hands of the worker.

Switchgear protection

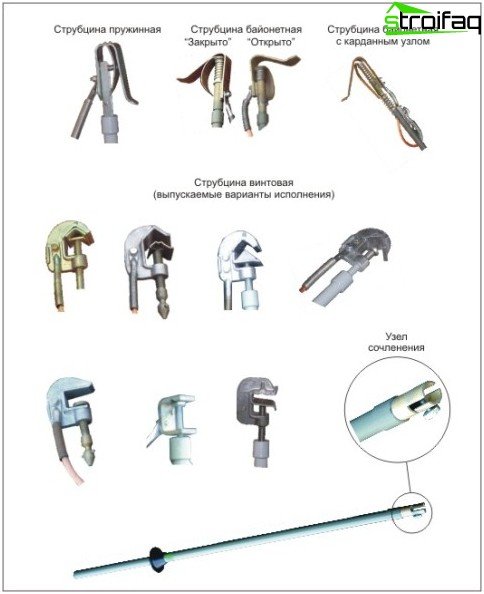

Damage due to induced voltage from the neighboring circuits or erroneously supplied voltage to the switchgear will help to exclude portable grounding systems that differ in the specifics of the installation in the switchgear. Installation of phase clamps can be done on cylindrical or spherical tips, on conductive busbars or at the points of location of fuses. Structurally, all devices are identical, the installation site is regulated by the purpose of the work and the features of the maintenance of a particular electrical installation.

The list of requirements for protective systems

Reliable in use, not causing inconvenience in installation, creating an impassable barrier to risks, portable equipment meets the following requirements:

- Impeccable dynamic strength. Clips should not break from the efforts of electricians.

- Thermal resistance to short circuit current caused by grounding. The elements of the device must not burn, melt, overheat from exposure to extremely high temperatures, otherwise high voltage will appear on the burned and melted ends.

Connections of conductors in portable earths are made by welding or crimping. If the conductors were connected using bolts, the mount is duplicated for strength by brazing. Earthing with soldering without additional fixing elements is not allowed for use, since the solder can melt. For the same reason, which implies overheating during a short circuit, copper wires of portable grounding are not insulated..

Portable grounding devices use copper wires without insulation, since the insulation can melt at extremely high temperatures.

Grounding requirements

According to technical regulations, portable grounding is installed on the elements of all phases of the area completely disconnected from the power supply. Disconnection is performed at all points of the connection, from which voltage could come from, taking into account also the reverse transformation.

One grounding is applied on each side, which is a sufficient condition for ensuring electrical safety. It is possible to separate the site from live parts using disconnectors, automatic machines, switches, it is possible to separate by removing fuses.

Between places of imposing portable grounding there should be a visible gap separating the device from live parts with unstressed voltage. The distance between live parts that remain energized and the work area must ensure safety.

The installation of portable earthing in closed distribution systems is carried out on live parts in places intended for the location of this particular safety feature. They are cleaned of paint, and the outline is indicated by black stripes..

Note. The places cleared of paint, intended for connecting portable grounding systems to protective wiring, must be adapted to fix the device clamps or equipped with clamps.

Portable Ground Fastener – Clamp

If portable electrical grounding cannot be imposed in electrical installations for good structural reasons, it is necessary to carry out additional important measures that increase the safety criteria. It is possible to exclude accidental or erroneous supply of voltage by fencing the upper contacts or knives with rigid insulating linings, rubber caps, or by locking the drive device of the disconnector.

Installation of portable grounding devices

Before applying grounding by installing an insulating rod, make sure that there is no voltage. According to the standards, two people are engaged in the installation and dismantling of portable grounding. Before checking for the presence or absence of voltage, ground must be connected to the Earth terminal..

Attention. On the hands of performers involved in the installation of the bar must be dielectric gloves.

Important. The use of conductors not intended for grounding is prohibited. Do not connect conductors by twisting.

- The ground conductor and ground wiring are connected.

- The voltage indicator checks its absence on current-carrying elements.

- Clamps are applied alternately to the live parts from all supplying parts during operation but disconnected during repair of the sides alternately with the help of a rod.

- Fastening is also carried out using a rod.

Note. If the clamp cannot be fixed when using the rod, it can be fixed manually, but only with dielectric gloves (only if it is used in installations with voltages up to 110 kV). Dielectric gloves are needed to carry out literally all activities: from overlay to removing a grounding portable device.

Personal Safety – Dielectric Gloves

Installation of portable protective equipment is carried out standing on the floor of the workshop or on the ground, sitting on a ladder, preferably wooden or made of another dielectric. It is strictly forbidden to climb installations or structures before checking for voltage.

Important. Voltage is not induced on current-carrying conductors only in case of ground connection. Immediately after removing the voltage, before applying the ground and after removing the ground, do not touch live parts without special protective equipment.

How to remove portable grounding

To remove the grounding system, the entire list of works is carried out in the reverse order. Any work is carried out only with gloves made of dielectric material. First, the device is removed from live parts, then disconnect from grounding devices.

All work related to the repair and modernization of electrical installations is dangerous. Failure to comply with the rules often results in tragic consequences. Neglecting collective electrical safety equipment, you should not expose yourself to unjustified risks..