How to insulate the floor in the bath

The floor in the bathhouse is exposed to moisture and high temperature, so it is necessary to approach its device with particular care. After all, the life of the entire structure will depend on the quality of the floor. At the same time, it is necessary to ensure the flow of water into the bathhouse into a specially arranged drain hole, for which the floor is done with a slight bias. Depending on the functional purpose of the room, the material for the floor device is selected in the bathhouse. However, in any case, it is required to consider its insulation. Many beginner builders do not know how insulate the floor of the bath, what materials to choose for this.

Content

- Concrete floor insulation

- Foam insulation

- Environmental friendliness of foam

- How to insulate the floor with polystyrene foam: progress

Concrete floor insulation

The concrete floor is easy to maintain and durable. Most often it is done in the washing department. The device is started after the drainage system is completed, the roof is made, windows are glazed, door blocks are installed, and all finishing work is completed. Since the concrete is cool and slippery, it is necessary to cover it in the bathhouse with special removable wooden grilles. For this purpose you can use mats made of twigs or flooring made of wooden battens..

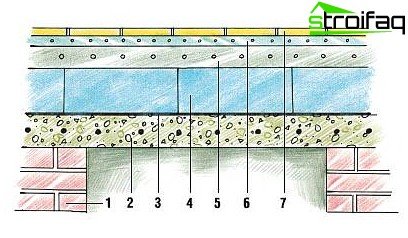

The diagram shows the design insulated floor concrete:

- foundation;

- floor made of concrete slab;

- waterproofing layer;

- extruded polystyrene foam in the role of insulation;

- mesh reinforced concrete screed;

- underfloor heating system and adhesive layer;

- floor tiles.

A common arrangement of structural and insulating elements of floor insulation with expanded polystyrene

One of the effective ways of installing this type of floor is to lay a heat-insulating layer made of glass wool, expanded clay or perlite, between two layers of concrete.

Perlite is called expanded sand, which, being a light material, is characterized by low thermal conductivity.

Thermal insulation of the floor in the bath can be done with perlite

Important! The room should be kept closed when working with perlite, otherwise it will fly upwind.

Procedure for insulation with perlite

1. Take two buckets of perlite and carefully mix with one bucket of water. Then cement is added and this mixture is thoroughly mixed. Then pour another bucket of perlite and pour no more than half a liter of water. All components are mixed again, and they do this until water is released from the solution. This sign indicates that the mixture for laying the insulation layer is ready.

2. Spread the prepared mixture on a concrete slab with a thin layer, leaving it alone for a week to dry.

3. After laying the second layer of concrete mortar. The heat-insulating layer, made in the form of a layer, will last for many years.

Foam insulation

The use of the latest foam materials having a closed cellular structure allows for the most effective floor insulation in the bathhouse. The special structure of polystyrene foam is characterized by almost zero water absorption, maintaining its insulating qualities for a long time. Expanded polystyrene is not susceptible to penetration of water, this distinguishes it from other heat-insulating materials having an open cellular or fibrous structure. Low thermal conductivity of foam plates is perfectly preserved regardless of moisture, as well as mechanical stress. This material is recommended for insulation in brick saunas. After all, a brick is a conductor of moisture from the soil and the environment.

To insulate concrete floors covered with tiles, laid on a level surface of the screed, use foams that have high compressive strength. Experts recommend using the following materials:

- Styrodur – durable green boards manufactured by BASF (Germany);

- Natur-III-PZ – heat-treated corrugated plate;

- Natur-III – compacted smooth plate;

- Roofmate – an insulating solid board painted in blue;

- Penoplex.

Environmental friendliness of foam

The materials used to insulate the floor in the bath should be environmentally friendly. In this regard, extruded polystyrene foam fits perfectly. Indeed, the foaming of this material is provided with the help of ordinary carbon dioxide. This means that no dangerous gas reagents contained in freons are present in it..

Polyfoam is convenient for use in construction, because it can be cut with conventional tools. At the same time, as a rule, it is possible to avoid the appearance of waste, which affects the reduction in the cost of thermal insulation work. Weightless slabs do not burden either concrete floors or foundation designs. The horizontal installation of the heat insulator is carried out on a perfectly flat substrate. The foam is not afraid of contact with water, since it is not subject to biodegradation.

How to insulate the floor with polystyrene foam: progress

Work on the insulation of the floor in the bathhouse is carried out in several stages.

Foam floor insulation

1. After laying the foundation and installing a concrete slab, waterproof the future floor.

2. Next lay the insulation – foam boards. The thickness of this layer can be from 10 to 25 cm.

3. A concrete screed is placed on top of the slabs using a reinforcing mesh.

4. The adhesive with the underfloor heating system is applied to the screed, laying ceramic tiles.

Insulation of the floor, as well as the walls and ceiling of the bath, allows you to ensure minimal heat loss in this room.

Warm wood floor

During the construction of the bath, many masters choose wood materials for flooring. Because no tile can compare with an environmentally friendly floor made of wooden boards that can store heat for a long time. In order for such floors to last as long as possible, not succumbing to decay, they must be properly prepared and thermally insulated.

Spruce, larch, pine and fir are suitable as the material for the device of the wooden floor of the bath.

Important! Strongly advise against the use of the following wood species: linden, poplar, aspen and oak.

Types of wood floors

Wooden floors in the bath are of two types:

- leaking;

- not leaking.

Leaking floors, based on the name, allow water to drain into the ground under the bathhouse through the gaps between the boards. Such floors do not require large investments of material resources, as well as labor costs. However, they have a very big drawback. These floors are cold, so they are recommended for use in the southern regions..

Non-leaking floors have a draft floor on which insulation is laid between the logs, which serve as supports for the finish coating. For the outflow of water, a hole is made in the floor that leads to the water collector, and from there it is discharged outside the bathhouse through a sewer pipe drain pits or septic tanks. The pipe in diameter should reach 150 mm, this will allow water to quickly leave the washing compartment. Non-leaking floors are made under a slope, which allows you to not stagnate water. Currently, this type of wooden floor is preferred during the construction of bathhouses..

A waterproofing layer is placed in the bathhouse on top of the “non-leaking” wood floor insulation, the lumber is impregnated with antiseptics and flame retardants

All floor boards laid in the dressing room and rest room are covered with a special antiseptic. It will effectively protect the wooden floor from damage by the fungus, as well as resist the beginning of the rotting process. For flooring in the steam room, dried wood is used, which is not treated with special compounds. Indeed, under the influence of steam, evaporation is possible, which will harm the human body. A well-dried floor will not rot during operation, it will only darken.

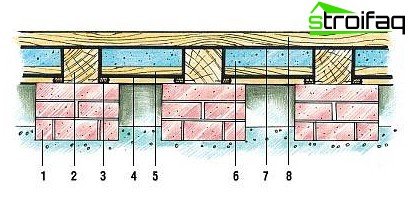

The scheme of warming a wooden floor

The figure schematically shows the construction of a wooden floor with insulation:

- foundation; floor beams;

- cranial beam;

- vapor barrier layer;

- rough floor;

- extruded polystyrene foam – insulation;

- waterproofing layer;

- batten.

How to insulate a wooden floor in a bath

As a heater with the device of the wooden floor in the bath mineral wool mats, fiberglass mats, slag, sand, expanded clay can be used.

Using a removable wooden floor

Also today, the use of removable wooden floors is practiced in saunas, the wet boards of which are removed, and dry ones are put in their place. The process is quick and easy, because the boards are not nailed. Wet boards are subjected to natural drying in the sun or forced in special drying chambers. Then the replacement process is repeated. Thus, the use of a wooden floor is extended.

In this article we tried to give you an idea of how to insulate the floor in the bath. All work, if desired, can be done with your own hands..