The roof of the bathhouse not only protects the building from the effects of the external environment – rain and snow, high temperatures in summer and low winters. It has another purpose – to resist the penetration of steam from the inside, formed in large quantities from water poured on stones, and also to cover the hot ceiling, the temperature of which often reaches 100 degrees Celsius. Therefore, those who decided to build a bathhouse should definitely think about how to insulate the roof of the bathhouse so that it was as vaporproof as possible and had good ventilation.

Content

- Common roof options for a bath

- Why you need to insulate the roof of the bath?

- Which thermal insulation material to choose?

- Ways of laying insulation

- Insulation of the roof of the bath: how to do it

- Ceiling insulation

Common roof options for a bath

The type and shape of the roof for the bath depends on the design of the building. If the bath room is an extension to the main building, then for it usually equip a pitched roof. For a separate bath structure, a gable roof is the optimal solution. In this case, you can equip a functional attic. These two roof options are used most often, since both of them are economical and easy to install. The slope of the gable roof is designed taking into account the climatic conditions of the region: in an area where there is a lot of rainfall, it is made sharper, and in areas where strong winds rage, the roof of the bathhouse needs to be made more sloping.

Why you need to insulate the roof of the bath?

Regardless of the design of the roof for the bath, it should protect the building from external influences and, most importantly, not to release heat from the washing and steam rooms. These functions can only be performed by a well-insulated roof. If it is assumed that the bath will be used only occasionally, then its roof can only be insulated with roofing material or glassine, before the flooring of the roofing material. If you plan to use the bath regularly, you need to warm it more reliably. Firstly, all structural elements should be protected from rotting with antiseptic solutions. Then, for fire safety, all wooden parts must be treated with flame retardants. And only then can you go directly to warming.

Which thermal insulation material to choose?

In past times, the roofs of bathhouses were insulated with such natural materials as tow, moss, hemp, and felt. Yes, these materials are cheap, environmentally friendly and have excellent thermal insulation properties, but at the same time they have significant disadvantages:

- subject to decay;

- attractive to insects;

- their installation requires a lot of labor.

Currently, developers use modern insulation materials as a heater:

- mineral wool;

- polystyrene foam;

- glass wool;

- jute;

- interventional insulation made of wood shavings.

They are resistant to high temperatures, moisture resistant, have high thermal insulation characteristics. An important characteristic for a bath heater is its environmental friendliness. It’s no secret that under the influence of high temperature, some synthetic materials emit toxic substances, but in the bath people want to improve their health, and not to ruin it.

When choosing a heater for the roof of the bath, it is advisable to give preference to environmentally friendly materials

Among the safe thermal insulation materials, mineral wool, Penoplex boards, extruded polystyrene foam, and felt can be recommended. Expanded clay crumb is suitable for the attic floor.

Ways of laying insulation

The insulation of the roof of the bath is carried out in three ways:

- Laying a layer of insulation on the rafters.

- Laying a layer of insulation between the rafters.

- Laying a layer of insulation under the rafters.

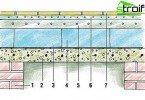

To create high-quality thermal insulation, the insulation layer must be continuous. Particular attention should be paid to laying the insulation in the places where the pipe exits, the ceiling adjoins the walls, etc. For ventilation it is necessary to leave an air gap between the waterproofing material and the heat-insulating layer of the roof. When using fibrous insulation, you need to leave the air gap a little more, since the thickness of the insulation layer increases in this case by almost a third. Sometimes the thickness of the rafters is insufficient to create a normal air gap. Then the desired height is increased using bars or boards.

Insulation of the roof of the bath: how to do it

Before starting roof insulation, it is necessary to protect structures from rotting and high temperature. To do this, the rafters, beams and the surface of the roof are treated with antiseptics and flame retardants.

Before the start of insulation, all wooden elements of the roof of the bath are treated with antiseptics to protect against decay and fire retardants for fire safety

A waterproofing material (membrane film or polyethylene) is reinforced along the entire roof surface. The film is spread before installing the lathing and fixed with an overlap (10 cm), without tension.

The vapor barrier film prevents the penetration of moisture into the insulation

The next step is the direct installation of insulation. The most popular material for insulation of the roof of the bath is mineral wool. It is a low-cost environmentally friendly material with excellent performance, easy to install.

Choosing mineral wool as a heater, you need to properly prepare the thermal insulation layer. The insulation is laid in two rows in a checkerboard pattern (the joints of the lower layer should not coincide with the joints of the upper). The optimum material thickness is approximately 100 mm. Then it is placed in a roofing cake. With this method of insulation, the formation of cold bridges that occur when overlapping joints is eliminated is excluded. If the roof of the bathhouse is not insulated during construction, but after the bathhouse is ready and the roof is already covered with roofing material, then the roofing cake is formed in the same way, only the insulation is laid from the inside, from the attic.

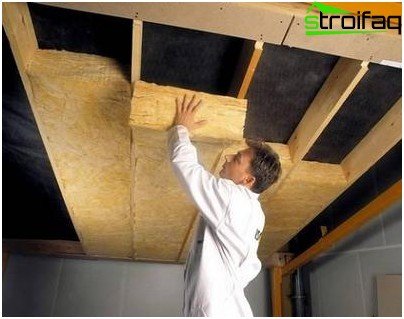

Laying insulation (mineral wool) between the rafters from the attic side

In this case, the fastening of hydro- and vapor barrier films and the insulation itself will be carried out in other ways. The ideal method of warming the roof of an already finished bath is to lay a layer of insulation between the rafters. The material is placed in the inter-rafter space, while it is necessary to observe the correct sequence of layers of the roofing cake. Thermal insulation material should be laid close to the rafters, in other words, the width of the sheet should be equal to the pitch between the rafters. When laying the insulation, it is necessary to prevent the formation of cracks and gaps. The vapor barrier film is lapped over the rafters. If several layers of insulation are used, then each subsequent layer is laid so that it overlaps the joints of the previous layer.

Ceiling insulation

Having finished with roof insulation, you need to do the thermal insulation of the ceiling. Insulation of the ceiling is also necessary, as it solves several important problems:

- protects the roof of the attic from moisture coming from inside the bath;

- retains heat and steam inside the steam room;

- prevents condensation on the ceiling.

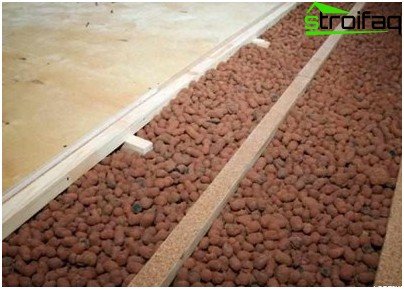

Insulate the floor in a log bath as follows. Ceiling of the ceiling is carried out with wooden blocks at least 6 cm thick and vapor barrier in the form of aluminum foil is laid on them. The foil is mounted with an overlap and fixed with a construction stapler, and the joints are glued with tape to ensure their protection against damage. Next, a heater with a layer thickness of at least 15 centimeters is laid on top of the vapor barrier layer. If it is expanded clay crumb, the thickness of the layer should be more than 25 centimeters, so a significant amount of this material will be required to warm the ceiling.

Expanded clay – an excellent thermal insulation material for insulation of the ceiling of the bath

The ceiling should be sufficiently insulated so as not to let hot air pass from the bathhouse. At the exit section of the chimney, you need to make sure that the distance to the ceiling boards is at least 25 centimeters. For fire safety, it is recommended to cover the edges of the boards with asbestos.

High-quality insulation of the ceiling eliminates the loss of hot air from the steam room

Sometimes, to insulate the ceiling, an old, time-tested “grandfather” method is used – coating with a mixture of clay and sawdust. The advantages of this method are environmental friendliness and low cost, but the implementation of such work is quite complicated. If you plan to arrange a utility room in the attic, the insulation is sheathed with boards from above, and in the case of a cold attic, a cement-sand screed will be sufficient. Insulation of the roof of the bath will not be effective without ventilation. Therefore, in the attic should arrange ventilation openings located opposite each other. To the heater air will enter through the air gap left during installation. This will prevent the formation of condensation in it..

Insulating the roof of the bathhouse on your own is a responsible and difficult task, requiring knowledge of many nuances and following some rules. Therefore, in the absence of practical skills in this matter, it is better to entrust the work to professionals and then your bathhouse will fulfill its mission without problems.