Electric jigsaws have found their place among modern building tools. With their help, you can finish cut various materials, and even from different angles. If you use the appropriate files, you can saw wood with a thickness of up to 12 cm, as well as mild steel with a thickness of not more than a centimeter. In addition, you can purchase files that are designed to work with sheet material of small thickness. Let’s find out, how to choose the right jigsaw file.

Each material corresponds to a file designed for working with it. Using a jigsaw, you can work with plywood, laminate, plastic, boards with nails, aluminum, sheet metal, fiber, cement, sandwich panels and other material. And this is not a complete list of materials for which files are used. A modern jigsaw is a universal tool that allows you to perform a wide range of work.

Varieties of jigsaw files

There are various types of jigsaw files. Many manufacturers have their own classifications, names and designations. In length, these components have from 7 to 13.2 centimeters.

The whole abundance of types of saws can be divided into two types: files with a special shaping of the teeth that allow you to perform a final cut, as well as files equipped with a special sharpening for quick sawing. The latter type is designed to operate at high speed. Quite often, on the packaging or directly on the jigsaw file you can see the inscription Clean CUT or Clean for Wood, which correspond to certain materials.

Various options for the position of the teeth of the file allow you to avoid getting stuck in the material. There are various approaches that allow you to form a profile file for jigsaw. With a wavy profile, when the teeth are located in a wave, it becomes possible to work with a variety of materials, without fear that the file will get stuck. In other files, the teeth can be grouped in pairs, which increases the cutting speed. In some files, the location of the teeth resembles their breeding in large hand saws, these details show good results in working with plastic and wood. Some companies produce teeth with a progressive pitch, which increases the frequency and speed of cutting.

What to look for when choosing a jigsaw file

To file fixed in a jigsaw, it is made with a shank. Universal shanks are especially widespread today. Finishing cuts are used to cut materials without burrs and at high speeds..

For fast sawing effective files, the distance between the teeth of which is large. They show good results in working with thick materials. Due to the large distance between the teeth, a high cutting speed is achieved..

Thanks to the use of saws with a small distance between the teeth, you can get a clean cut, and besides, even painted materials can be cut with them, without worrying that you will peel off the paint.

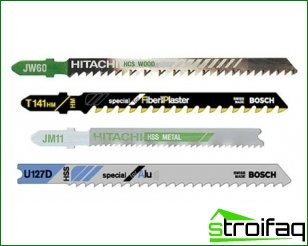

Designations on jigsaw files

For the manufacture of jigsaw files, modern high quality materials are used. On their company packaging you can see the designation of the material that was used for their release.

The HSS designation indicates that the product was made of tool steel. These files are used to work with materials with high hardness: aluminum, steel and various non-ferrous metals.

If the product is marked with HCS, this means that high-carbon steel was used for its manufacture. These files will be an ideal solution for working with materials with low hardness: fiberboard, wood, rubber, chipboard, plastic, etc..

Saws made of hard alloys are designated NM / TC. They are used in work with abrasive and hard materials, steel, fiberglass, tile and other.

The BiM designation indicates that the product was manufactured by combining the HSS and HCS types. The result of using this technology is bimetallic files, characterized by strength and flexibility. Using these files, fast sawing is performed, and they work with almost any material..

If you succeed choose the right jigsaw file, It will serve you for a long time, showing high efficiency and productivity. It was thanks to them that an electric jigsaw was able to displace hacksaws and hand saws in some areas.