Among the construction tools today, electric jigsaws are widely used, which allow for various kinds of fine sawing at various angles. Thanks to the use of certain files, you can perform work on sawing materials from wood, up to twelve centimeters thick or centimeter mild steel. There are other files that meet the requirements for sawing sheet material. So what is optimal selection of jigsaw files?

First, it is worth noting that with such a universal tool as a jigsaw, which allows you to perform a fairly large amount of all kinds of work, you can work with the following materials: plastic blanks, plywood, laminate materials, wood (containing nails), sheet metal iron, aluminum blanks, cement materials, fiber and many others (the list is superficial).

How do nail files differ

In addition to the distinctive types of files, modern manufacturers of this product have their own divisions by class and specific designation. As a rule, nail files in length have sizes from seven to thirteen-plus centimeters.

Despite the huge selection of files available, they are all divided into two main types. The first is with specially made tooth shaping, which allows for clean sawing of the material. The second type is definitely sharpened files for high-speed sawing. On the packing box or directly on the file itself, there is often an inscription corresponding to the surface being treated – «Cut» or «for wood».

The files are made with all kinds of tooth arrangements on the blade, which allows it not to get stuck when cutting. Different profiles of the web itself are also used. For example, a profile with a wave arrangement of teeth provides the ability to easily work with a wide variety of workpieces, while the file does not get stuck.

A profile with a group of teeth in pairs, as well as teeth with a certain step, makes it possible to increase the cutting speed of the material.

What to consider when choosing a file

For information, it is worth noting that on many files there is a tail for fixing in the tool. Nowadays files with universal tails are very common..

First decide on the front and the objectives of the intended work. The large distance between the teeth of the file is very effective for work on the fast sawing of materials. They have also proven themselves in cases with thicker sawing. On the other hand, using a file with a small intermediate separation of the teeth, you can count on a clean cut without burrs. Thanks to such a cutting file, painted materials are perfectly sawn, since there is no need to be afraid of chips on a painted surface.

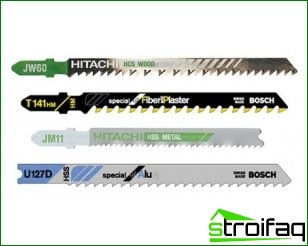

Some marks and markers on files

Files are made using modern materials of very high quality. On the packaging box are some designations of the material used in the production of this component product. For example, abbreviation «Hss» means that the file is made of high-speed tool steel. Basically, such files are used when working on solid billets and materials (steel, aluminum and billets of different non-ferrous metals). If the abbreviation is applied to the file «HCS», then the component is made with high carbon steel content. Files of this manufacture are usually used when working with materials that do not have high hardness, for example, chipboard, rubber blanks, fiberboard, wood material, plastic and others. As for the files made using durable alloys, they are marked «NM / TS» and are largely used when working with strong abrasive materials: tiled, steel, fiberglass and the like.

Among the construction tools today, electric jigsaws are widely used, which allow for various kinds of fine sawing at various angles. Thanks to the use of certain files, you can perform work on sawing materials from wood, up to twelve centimeters thick or centimeter mild steel. There are other files that meet the requirements for sawing sheet material. So what is optimal selection of jigsaw files?First, it is worth noting that with such a universal tool as a jigsaw, which allows you to perform a fairly large amount of all kinds of work, you can work with the following materials: plastic blanks, plywood, laminate materials, wood (containing nails), sheet metal iron, aluminum blanks, cement materials, fiber and many others (the list is superficial).

How do nail files differ

In addition to the distinctive types of files, modern manufacturers of this product have their own divisions by class and specific designation. As a rule, nail files in length have sizes from seven to thirteen-plus centimeters.

Despite the huge selection of files available, they are all divided into two main types. The first is with specially made tooth shaping, which allows for clean sawing of the material. The second type is definitely sharpened files for high-speed sawing. On the packing box or directly on the file itself, there is often an inscription corresponding to the surface being treated – «Cut» or «for wood».

The files are made with all kinds of tooth arrangements on the blade, which allows it not to get stuck when cutting. Different profiles of the web itself are also used. For example, a profile with a wave arrangement of teeth provides the ability to easily work with a wide variety of workpieces, while the file does not get stuck.

A profile with a group of teeth in pairs, as well as teeth with a certain step, makes it possible to increase the cutting speed of the material.

What to consider when choosing a file

For information, it is worth noting that on many files there is a tail for fixing in the tool. Nowadays files with universal tails are very common..

First decide on the front and the objectives of the intended work. The large distance between the teeth of the file is very effective for work on the fast sawing of materials. They have also proven themselves in cases with thicker sawing. On the other hand, using a file with a small intermediate separation of the teeth, you can count on a clean cut without burrs. Thanks to such a cutting file, painted materials are perfectly sawn, since there is no need to be afraid of chips on a painted surface.

Some marks and markers on files

Files are made using modern materials of very high quality. On the packaging box are some designations of the material used in the production of this component product. For example, abbreviation «Hss» means that the file is made of high-speed tool steel. Basically, such files are used when working on solid billets and materials (steel, aluminum and billets of different non-ferrous metals). If the abbreviation is applied to the file «HCS», then the component is made with high carbon steel content. Files of this manufacture are usually used when working with materials that do not have high hardness, for example, chipboard, rubber blanks, fiberboard, wood material, plastic and others. As for the files made using durable alloys, they are marked «NM / TS» and are largely used when working with strong abrasive materials: tiled, steel, fiberglass and the like.

If the file was made taking into account the combination of such types as «Hss» and «HCS», it is indicated by a marker «Bim». This technology has led to the creation of bimetallic files that are durable and flexible. The advantages of these files are the ability to process any material and perform accelerated sawing.

The optimal choice of jigsaw files – the key to your successful and high-quality work. Having picked up the necessary type of file in advance for the task, you will greatly facilitate your work and enjoy the work. As for the file itself, it will last a long time without losing its qualities, efficiency and productivity. In some areas, a jigsaw with a file of good material can give you far more options than hand saws or hacksaws..