3D filler floors

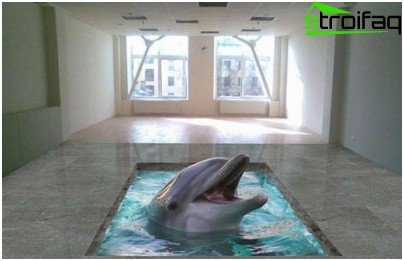

If you have to replace the floors, but you can’t decide on the choice of technology (there was already a laminate, a long time to lay the parquet, the tiles are cold, and so on ad infinitum), pay attention to 3D flooring. Among other advantages (high performance), the possibility of embodying any design idea is especially notable, especially impressive Self-leveling floors 3D – photos of ready-made interiors amaze with the created effect of a three-dimensional image on a plane.

Content

- Polymer floors: pros / cons

- Room design with 3D floor

Fill floor with 3D 3D effect of a plane image

A popular novelty can be a worthy replacement for such practical and beautiful floor coverings as laminate or linoleum. Floors made using transparent polymeric materials are characterized by high wear resistance, strength, resistance to moisture, the development of various fungi and mold. Smooth transparent coating is very hard and durable, especially interesting in terms of the implementation of various design solutions.

The manufacturing technology of the self-leveling floor allows you to get an almost unique floor covering: various objects (pebbles, leaves, beads) are laid out on the prepared surface, and a clear solution with a hardener is poured on top.

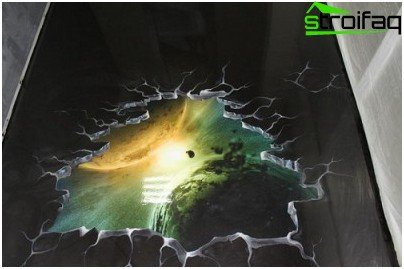

As you can see, the technology of manufacturing newfangled 3D floors is quite simple, but, of course, requires accuracy and certain skills in the work. The desired effect is achieved by coating with a transparent composition of a specially prepared printed image.

Flood floor with 3d effect provides the opportunity for widespread imagination of designers: you can realize just about any idea

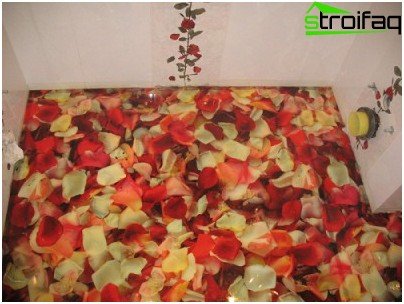

The bulk floor can be of any shade, it can contain any image, including with a 3D effect. This floor is easy to clean, it is seamless, which from the point of view of hygiene is an indisputable advantage – there is nowhere to accumulate dirt. The floor is abrasion resistant and aesthetic. Along with increased strength, the bulk coating is characterized by low electrical conductivity.

Flooded floor, high precision print image used

Polymer floors: pros / cons

Consider the advantages of flood 3d floors:

- environmental friendliness;

- strength;

- do not conduct electricity;

- good thermal conductivity;

- resistance to acids;

- resistance to burnout;

- the floor is monolithic (does not contain seams).

High cost is the main disadvantage. 3D filler floors will cost 4 times more than a laminate flooring. To a large extent, the cost depends on the expensive printed image (the image is applied to a special fabric, always high print quality). The essence of 3D image technology is to create the illusion of a three-dimensional image on a plane when viewing from a certain point. But to achieve the desired effect, you need a lot of space.

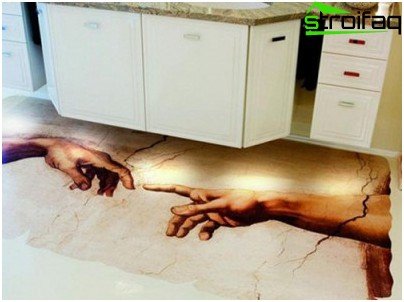

In a large room, a large drawing is quite appropriate

Self-leveling floors can effectively simulate various surfaces, which is achieved using prints with a two-dimensional graphic image of high print accuracy. The transparent polymer layer additionally creates the illusion of volumetric pattern. Depending on the thickness of the transparent layer, thin-layer and highly filled flooded floors are distinguished.

The latter can be used in places of industrial importance due to the increased strength and resistance to abrasion. Perfectly flat plane – the main condition for uniform coating.

Room design with 3D floor

A few tips from the designer:

- free the central space from furniture (the 3D floor is already an active element of the decor of the room, try not to spoil the interior with unnecessary additions);

- for a better view, place the picture along the longest wall in the room;

- the abundance of bright contrasting details in the floor design can visually reduce the room, if it is desirable to visually increase the space – avoid bright colors.

No coating can create such a realistic effect.

It is widely believed that 3d flooring is best used exclusively in the bathroom. Indeed, a perfectly even coating is resistant to increased humidity, is durable, resistant to chemical stresses, which makes it possible to use it when arranging floors in the bathroom, but you should not limit yourself to the bathroom only.

Jellied 3D floor in the nursery: bright, colorful, energizing

In fact, the scope is much wider – 3D floors will effectively complement the interior of a cafe or a trading floor of a large supermarket (floor life is 30-40 years). The use of polymer floor coverings for flooring in residential premises is welcome, because the installation uses environmentally friendly materials, the coating is hygienic, can be used under the “warm floor” system. It is possible to produce a smooth, moderately rough or rough coating.