Today, polymer floors are very popular in modern construction, and well-deserved. These are seamless coatings that attract with their performance, not too high cost and durability. In addition, they are the most unpretentious and beautiful, so apartment residents prefer them.

Content

- Advantages of Polymer Flooring

- Types of polymer floors

- Application technology, features

- Self-leveling floor

- Innovative coating 3d

Advantages of Polymer Flooring

Polymer Self-leveling floors – high-tech coatings with such unique properties that are incomprehensible when using concrete, linoleum, ceramics, that is, traditional materials.

Polymer floor attracts a huge number of decorative variations, seamless surface, long-term

Indeed, the advantages are significant and worthy of the attention of consumers:

- durability – their use pays off due to the long service life (provided that it is used correctly, up to 15 years) and reliability;

- heat resistance – good resistance to high / low temperatures;

- wear resistance – exceptional indicators to abrasive wear;

- chemical resistance – this is more true for epoxy floors, they are not afraid of solvents, alkalis, salts;

- elasticity – in particular, this advantage relates to polyurethane coatings (any cracks in the concrete coating overlap);

- hygiene and harmlessness – full compliance with sanitary and epidemiological standards, that is, when applied, they are completely harmless. Moreover, neither bacteria nor microorganisms start on them;

- dust-free – one of the main problems of concrete floors has been solved.

Seamlessness is also very relevant for machine cleaning, floors are quickly applied and after 24-48 hours you can walk on them. And the most important advantage – a lot of design solutions, various colors, and if desired, the bulk floors in the apartment can be made in several colors.

But there are some disadvantages: you need to control the moisture content of the substrate and it is difficult to remove the coating in the future.

Types of polymer floors

Classification by type of coating:

- epoxy self-leveling floors – this is a two-component coating with an organic base, an excellent option for rooms with a high humidity index. It can be concluded that they are most suitable for bathroom and kitchen. In fact, this is the most common polymer coating in the world, because it fully meets the technical requirements and is characterized by a fairly low cost;

- polyurethane – have good impact resistance. This is a liquid one-component composition that visually resembles oil paint. This type is mainly used in the corridor and hallway, since there is an increased degree of surface abrasion;

- epoxy-urethane – suitable for places where there is a constant movement of people;

- methyl methacrylate – this type is out of competition for use in unheated rooms.

But as for the relief, the polymer coating for the floor can be smooth, rough and textured.

Application technology, features

If you want the apartment to be decorated with beautiful high-quality bulk coatings, it is better to contact professionals, because polymer floors are a specific and complicated technology (each type of polymer has its own technique).

Pouring the floor with your own hands start from the wall without a doorway

Real experts finish the floor so that it does not lose valuable properties, that is, nerves and the amount of materials will be saved. In fact, the whole process consists of several stages:

- preliminary grinding of the surface of the base;

- thorough dust removal;

- priming;

- base coverage;

- finish layer.

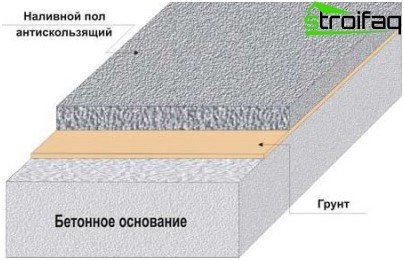

Floor scheme

Well, if you have confidence in your abilities and skills, and you are not from a timid dozen, then you can carry out all the work yourself. This will be discussed now..

Self-leveling floor

So, you decide to apply the polymer bulk floor with your own hands? Then you need to start with the preparation of the foundation.

Important: the positive properties of the future coating depend on this stage, as well as the absence of defects: roughness, swelling.

Many people are mistaken in thinking that only concrete can be the foundation of such a floor. This is a wrong opinion, as there may still be wood, ceramic tiles. So, we begin to prepare.

Wood – you need to ensure that on this basis there is no fat and oil, only dryness and cleanliness (dust is removed with a vacuum cleaner). Before applying the floor, the surface must be sanded or sanded. Humidity at work – 8-10%.

Important: a wooden coating is not a guarantee of strength, a very unpleasant surprise can be expected for you – cracks form on a thin layer of the floor.

Concrete – humidity is not more than 4%, the surface is clean, fairly even (without significant deviations), if necessary, a mosaic grinder is used. There are times when large cracks are present in the “native” concrete floor, then a self-leveling, self-leveling coating can be applied. They can also be glued with fiberglass, covered with sand, and after one day remove excess. And only after such preparation is applied the primer.

Ceramic tile – without fail, the tile must be securely attached. If there are problem areas, then bad tiles need to be removed, and the resulting gaps should be putty. Then the surface is washed, degreased with an organic solvent. Then a primer is applied that increases adhesion..

Important: degreasing is a mandatory procedure, without it, adhesion is reduced.

The next stage of work is priming. It is necessary in order to close the porosity of concrete and prevent air from entering the floor surface, because as a result of this, defects will appear. Quartz sand is added to the applied soil (roughness is formed), i.e., adhesion to the base increases.

Important: the sand should be dry, clean, fine.

There should not be any difficulties with priming. Soil is simply bought in the store and applied with a roller. If it is highly absorbed, then it is advisable to carry out the procedure twice. At the same time, it is not worth saving on the primer, the price and expense are small, but the quality of the floor is significantly deteriorated without its use.

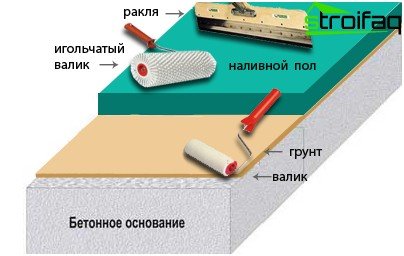

The poured polymer solution must be leveled before polymerization occurs.

Application of the main layer (base) – 6-12 hours after the above process (if it is polyurethane) and a day later, if the epoxy floor. These are average figures, so you need to pay attention to the terms indicated on the package.

Important: the floors in question are very sensitive to temperature differences during installation, so the amplitude of the oscillation should not be more than 2 degrees.

The base layer is a specific continuous coating (there are no defects on it), which is applied by pouring. So, everything happens according to this scenario: the polymer composition is poured onto the floor, which is then evenly distributed. If the work is large-scale, then the floor can be filled with squares in a checkerboard pattern or alternating stripes. Parts are connected due to spontaneous alignment and spreading of the mass.

The device of the bulk floor

The main working tool is a doctor blade, a special device with an adjustable gap (the required thickness is applied). But in hard to reach places you can use a spatula.

There is also another indispensable helper – climbing boots, boots on shoes, they have steel spikes on their soles. With their help, you can freely move on the applied floor without damaging it at all..

While the base layer dries, you need to roll aeration roller over it (with long spikes) a couple of times, with it air bubbles are removed.

A needle roller “passes” over the entire cast surface in order to remove air bubbles from the cast polymer composition

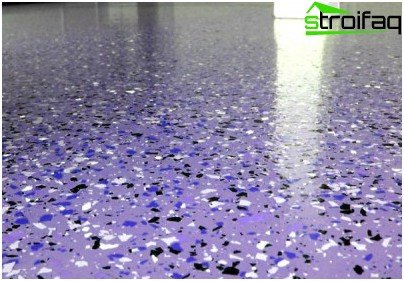

For greater beauty, you can apply “chips” to the coating – specific pieces of thin-sheet polymer, that is, create an original pattern and in one fell swoop hide the unevenness of the floor (if any). Then a transparent thin layer of polyurethane varnish is applied..

Important: self-leveling floors can be applied in one layer and several (interlayer grinding is performed).

The finishing layer – is poured 2 days after the base (thickness 1-2 mm), it is responsible for the color of the floor.

This type of flooring practically does not shrink, but nevertheless the temperature-shrinkable joints (along the walls, in the doors) must be cut, since the coating is applied to concrete and undergoes all deformations with it. These seams are then sealed..

Do-it-yourself polymer floors are a reality, it is necessary to adhere to the technology clearly and in 5-7 days it will be possible to contemplate a magnificent bulk coating. A very interesting option is a self-leveling polymer floor using large and colorful mosaics. Thin plastic strips are used as a separator, which are placed before work in accordance with the fill map. Such a wonderful cover looks amazing!

A few words regarding the cost, there is nothing complicated: polymer floors – the price depends on the evenness and / or the presence of a concrete base, on requests for decorativeness (uniformity, pattern, different colors), on thickness, on the type of polymer. It also includes the name of the manufacturer and the complexity of the installation (if external workers are hired). But if the owner of the apartment wants to get a chic bulk polymer floor – the price should not bother him, because the design plan can be very original. This will be discussed further..

Innovative coating 3d

Nowadays, they are becoming more and more popular. 3d polymer floors. This is a great way to express your personality, because many people are uninteresting and, at times, ordinary and banal. And this type of decorative flooring diversifies the interior, brings notes of originality and exclusivity. At the same time, the color palette is very wide, there is where to turn around and dream up. Such a variety of shades is an indisputable proof that the end result will be amazing, fashionable and unusual..

3d polymer floor gave designers an unlimited number of opportunities for the realization of fantastic ideas

What is their essence? Modern technologies open new horizons; when creating a decorative bulk floor, you can use stone, wood, metal, these materials look great under the transparency of polymers. Plus, it is possible to make different photos, drawings, logos and even reflective geometric shapes.

To be honest, they can not be called cheap and affordable pleasure. But it is very beautiful, in addition, the cost pays off with multiple positive characteristics (which have already been mentioned).

From the information provided it is clear that there is a choice, it all depends on personal desires. But no one will argue with the fact that the bulk floors embellish and enrich the design of the apartment, this is a fact.