Using a welding inverter is associated with various difficulties and dangers. Therefore, it is important to approach the choice of equipment with all responsibility and seriousness. The equipment is represented by various types and models, so you need to carefully approach its purchase.

Types of modern welding equipment

Welding inverters for summer cottages should be light and small, which will allow them to solve various household issues. An excellent solution may be equipment marked with MMA, for which conventional electrodes are used.

But in an industrial enterprise it is better to give preference to semi-automatic welding. Of course, the devices will have more weight, but their power will not be in doubt.

The welding technology with their help has its own characteristics – a special wire is supplied to the arc, playing the role of an arc catalyst and forms a weld.

Argon welding is characterized in that its arc is formed in an inert gas. The chemical element is passive, it does not react with metal. Welders can be designed for use with non-consumable and consumable electrodes. For the manufacture of the first type, as a rule, tungsten is used. However, the high cost and complexity of operation make them unsuitable for domestic use..

Key parameters to consider

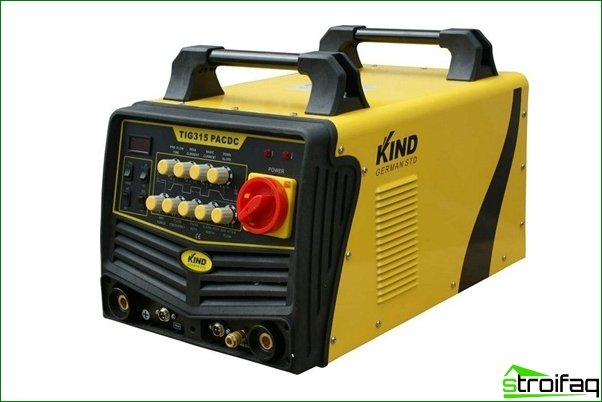

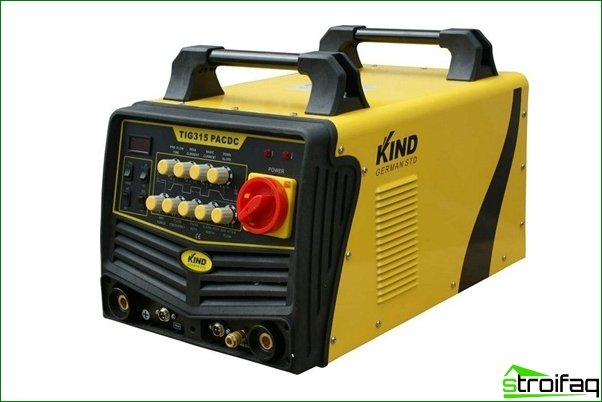

When choosing an inverter for welding, it is important to consider the type of current. Most often, there are models that work with direct current. If we talk about the voltage, then it can be at the level of 220 or 380 volts. This indicator should be selected depending on the power. For equipment with power above 4 kW, a mini transformer should be used..

Also important is the starting current. It can be in the range of 4-32 amperes. For consumer needs, a figure of 16 amperes will be enough. This indicator affects the thickness of the electrodes used. In everyday life, products with a thickness of 20 mm are used..

Using a welding inverter is associated with various difficulties and dangers. Therefore, it is important to approach the choice of equipment with all responsibility and seriousness. The equipment is represented by various types and models, so you need to carefully approach its purchase.Types of modern welding equipment

Welding inverters for summer cottages should be light and small, which will allow them to solve various household issues. An excellent solution may be equipment marked with MMA, for which conventional electrodes are used.

But in an industrial enterprise it is better to give preference to semi-automatic welding. Of course, the devices will have more weight, but their power will not be in doubt.

The welding technology with their help has its own characteristics – a special wire is supplied to the arc, playing the role of an arc catalyst and forms a weld.

Argon welding is characterized in that its arc is formed in an inert gas. The chemical element is passive, it does not react with metal. Welders can be designed for use with non-consumable and consumable electrodes. For the manufacture of the first type, as a rule, tungsten is used. However, the high cost and complexity of operation make them unsuitable for domestic use..

Key parameters to consider

When choosing an inverter for welding, it is important to consider the type of current. Most often, there are models that work with direct current. If we talk about the voltage, then it can be at the level of 220 or 380 volts. This indicator should be selected depending on the power. For equipment with power above 4 kW, a mini transformer should be used..

Also important is the starting current. It can be in the range of 4-32 amperes. For consumer needs, a figure of 16 amperes will be enough. This indicator affects the thickness of the electrodes used. In everyday life, products with a thickness of 20 mm are used..

These are not the only important characteristics. It is necessary to take into account the power of the device, its size, weight, open circuit voltage and other parameters. Of course, the purchase in this case will take much more time and effort, but this way you can purchase exactly the equipment that best suits your needs.