Do-it-yourself garage stove

Issues of heating garages in the winter have to be addressed to owners of buildings that are not connected to a centralized network or are not built into a single heating system in a suburban area. Often, an additional garage stove rescues motorists whose individual parking for cars is heated with insufficient efficiency. There are several ways to deal with the cold that adversely affects the car and prevents the owner from working in the garage. The choice of the appropriate option depends on the economic condition of the owner of the car and the type of construction for its storage.

Content

- Why do I need heating in the garage?

- Types of Garage Ovens

- The advantages of a wood stove

- Structural components of a potbelly stove

Why do I need heating in the garage?

The regulations regulate a temperature indicator favorable for car storage, it is 5 ° C and allows deviations of one degree. What happens to a car at a lower temperature is probably known to every motorist. Most of them, without a doubt, managed to face the laborious start of the engine in cold weather, especially noticeable after a long parking time..

From exposure to low temperature, even antifreeze can freeze. Car enthusiasts who use plain water to cool and drain it daily at night cannot fill the radiator with hot water. From this, the cylinder block frozen in the cold and the head of this unit may burst. Once in a very chilled environment, boiling water freezes in a couple of moments and clogs the channels with ice plugs.

Homemade stove – economical effective option

A primitive and expensive way to prevent these troubles is to operate the engine around the clock, which reduces the engine resource and entails high costs. Moreover, the owner of the car will still need to warm up the transmission with a blowtorch or an elementary bonfire. After reviewing the list of threats and gaining practical experience, the owner of the garage comes to the natural conclusion: he needs a factory heater or a home-made stove for the garage, which maintains a constant temperature regime with parameters dictated by the standards.

Types of Garage Ovens

Two main aspects influence the selection of the optimal heating method:

- the period of time during which it will be necessary to heat the garage;

- the amount the owner is able to invest in the furnace.

If the garage is a household extension to a residential building, it makes sense to equip it with heating devices with subsequent connection to a common network. In an autonomous garage, located far from residential buildings with communications, you will need to make an individual system.

All modern heating units for garages used today are classified based on the difference in the principle of operation of the energy source. You can equip the building by installing in the garage:

- Gas heating boiler. Quite productive equipment is distinguished by an affordable price, independence from power supplies. However, in areas that do not have access to central gas supply networks, this heating method is not possible. Explosion hazard.

- Units that supply thermal energy through the combustion of solid fuels. You can buy a factory-made stove for foreign or domestic production, you can make a simple stove for your own garage. This is the most rational method of heating in terms of costs and the resulting effect..

- Electric heaters, the attractive side of which is the ability to choose equipment with exactly the right capacity. Negative quality of systems powered by the mains, energy consumption with a rather big charge.

- Waste engine oil furnaces.

Heating electrical equipment is now represented by a wide range of factory products. The main argument in their favor is mobility, which allows the installation of units in areas that need maximum heating at the highest rate. Garage owners who are not too worried about energy consumption can buy infrared systems, oil coolers or heat guns in stores.

The equipment produced by manufacturers is equipped with devices with which you can set the direction of the heat flux and adjust the power. There are wheels for the convenience of moving equipment, systems that provide users with safety, preventing premature wear and breakdown of units. Heat guns and infrared heaters are also in the range of gas systems.

An extensive assortment of factory furnaces for the garage allows you to choose and buy a unit with any capacity that processes the optimal type of fuel for the owner

Productivity and efficiency are combined with equipment that runs on standard solid fuels, which use coal, special pallets, and firewood. They are produced in a wide range by industry. Heating systems made of heat-resistant materials from manufacturers in the simplest way described in the instructions are installed in the places specified by the manufacturers. However, an elementary wood-burning garage stove made by one’s own hands will be just as productive, only costing tens of times cheaper.

The advantages of a wood stove

An economical, self-made wood-burning stove is easy to maintain, many consider it the best option for arranging autonomously located garages. The most common design is a potbelly stove, the installation of which requires compliance with two main rules:

- The stove-potbelly stove can be used only in rooms with openings that provide air flow, and pipelines through which exhaust ventilation is carried out.

- It is necessary to install a heating structure in the garage area, remote from flammable objects, elements made of wood, from locations for lubricating, combustible consumables.

One of the options for a stove-potbelly stove can be installed only in garages with natural or artificial ventilation

In addition to profitability and the operational rate of heating the premises, the popularity of this design is justified by the following convincing advantages:

- the extremely low cost of equipment and the affordable price of the fuel required for its functionality;

- the ability to independently mount a productive, durable stove with minimal financial costs;

- excellent efficiency with small unit sizes;

- Cheap installation

- not laborious maintenance;

- lack of need for the construction of a special foundation for the stove;

- the ability to use a hand-made product for heating and cooking.

The disadvantages of this method are also available. The main among them is a rather large consumption of inexpensive, but taking away a certain amount of fuel. Firewood is quickly consumed because the metal structure is not able to accumulate the generated heat. The energy resulting from the combustion of firewood is immediately transferred to the air mass, but after the stove is no longer heated, the metal case cools very quickly.

There is a method of reducing fuel costs, consisting in the modernization of the design. A stove-potbelly stove will require significantly less wood if the pipe is mounted in the housing almost above the door, and not traditionally near the back wall.

Due to the displacement of the position of the nozzle, the walls of the stove will be heated first, and only then the combustion products will fall into the pipe. At the same time, the time for the release of thermal energy will increase, since a clay-concrete, insulated metal or brick pipeline cools more slowly than the body metal. In addition, the period required to heat the interior of the garage will be shortened..

Structural components of a potbelly stove

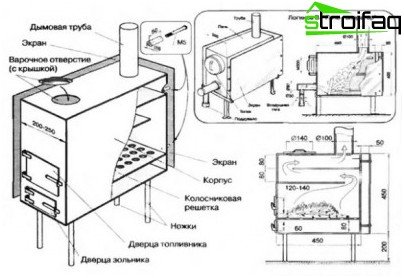

The variability of the designs of stoves of the “potbelly stove” type determines the absence of clear regulations. Each master does it at his discretion, in accordance with personal preferences. But no matter what scheme the manufacturer preferred, all heating units of this variety have common structural elements, these are:

The design scheme of the simplest stove-potbelly stove

- the firebox, which is a standard combustion chamber, its configuration and dimensions are not declared by strict canons;

- the grate installed at the base of the structure, it is needed to create traction and to place firewood;

- the chimney pipe, it can be curved or spiral, in the case of using a standard straight pipe, it should be noted that the length of the straight horizontally installed chimney sections according to building standards should not exceed 1 meter.

- an ash pan located under the grate, which is a device for collecting ash.

The simplest “bourgeois” stove consists of a metal case equipped with a door for supplying fuel, and a pipe, the location of which is determined by the manufacturer. As a blower, you can make small holes in the bottom, they will help create a good draft. The tortuosity of the chimney is dictated by the need to reduce the speed of movement of hot air through the pipe. The smoke, lingering in the chimney, will give off thermal energy to the room, and not “fly out into the chimney” with undesirable swiftness.

“Working out” furnace

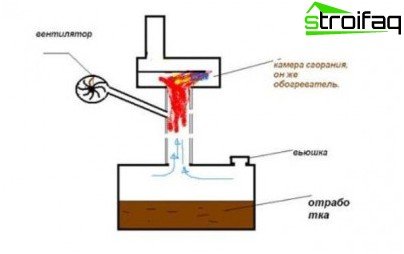

The main advantage of this heating equipment is the use of the cheapest, often free fuel. A simple reliable unit operates without a nozzle and dropper. This is an extremely cheap stove – it’s easy to make it with your own hands in the garage, it’s also not problematic to always find fuel for it.

The standard scheme of the stove for a garage that operates on waste oil, the dimensions the master can choose

The waste oil structurally processing furnace is two containers connected by a perforated pipe. The lower element with a volume of 12 l serves as a furnace and fuel tank. On the upper plane of the lower part of the stove there should be a hole equipped with a cover. A hole is needed for fueling, a cover is needed to control the operation of home-made equipment. Opening and closing the lid, the owner will control the supply of oxygen required for combustion, on which the heating productivity depends.

The upper tank and the pipe connecting the two main parts play the role of the heating elements of the furnace. This home-made device can become hot up to 800-900 ° C. So that the containers do not burn out for their manufacture, sheet metal with a thickness of 4 to 6 mm is used. A pipe is welded to the top of the stove, onto which a chimney made of galvanized steel alloy is installed. The entire furnace structure should not be monolithic, since the upper tank will need to be removed to remove soot from the burner.

The structural components of the future furnace for a garage that processes waste oil

How to make a stove with your own hands

For the manufacture of such a device, drawings, any in-depth technical knowledge, professional skills are not required. The unit will consume up to one and a half liters per hour, the whole system weighs no more than 30 kg. Standard dimensions that do not take into account the exhaust pipe vary from 35 to 70 cm. Most often, a pipe with a cross section of 105 mm is used to make the hood..

For those who want to know how to make the stove in the garage correctly, and how to be so that the operation of the homemade product does not cause problems, there are several important recommendations:

- The preferred chimney height is about 4 meters, which is necessary to form a good draft.

- The working stove needs to be cleaned every ten days.

- Soot will be much smaller if the diameter of the upper pipe is larger than the size of the exhaust element.

- The unit must be installed in the garage area so that there are no closely located explosive substances, combustible objects.

For the operation of the stove, oil with any degree of purification is suitable. An uncleaned composition is quite suitable. If you negotiate with the owners of nearby garages and put some kind of tank to drain the oil, the fuel for the stove will be completely free. Use for heating the garage can be transmission, transformer, engine oil, diesel, any heating oil.

A huge number of stoves for mining, having a similar design and working on a single principle

Such a homemade stove is fired up with the help of paper embedded in the lower tank, newspaper, over which fuel is poured. The contents will begin to boil in about ten minutes, the combustion process is initiated due to the ability of the oil to ignite spontaneously. Fuel is poured in portions of 5 liters. When using cleaned compounds, it will be possible to take care of structural elements less frequently, which will also be facilitated by an increase in the cross section of the chimney.

A functional, efficient oven for garage construction can be done with your own hands at minimal cost. Without any problems, exorbitant labor costs and professional skills, a novice master is able to make her able. Homemade stoves are easy to use, productive, safe to follow.