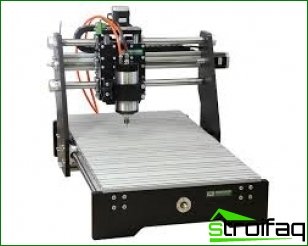

Metal processing is carried out using a variety of equipment, one of the most efficient and in demand is a CNC milling machine. The technique is quite complex and expensive, it is not surprising that you should choose it wisely before buying. Acron-System offers a wide range of branded equipment at affordable prices. It remains only to determine what exactly you need.

Key parameters to consider when choosing a CNC milling machine

Sometimes after acquiring a machine, business owners face various problems. Let’s get to know what to consider in order to avoid such consequences..

Determining the maximum size of the workpiece. This parameter will help to calculate the size of the working field of the equipment. In order to obtain the desired result, the workpiece must be processed from all sides, due to this the quality of the work performed is increased and does not require frequent readjustment.

Machine spindle. This item is one of the most important and expensive equipment. It is better not to buy equipment from little-known manufacturers, especially if the devices are liquid-cooled. High-quality spindles with good care can last at least five years. Another important parameter is its power – it should have some margin in comparison with the expected loads..

Metal processing is carried out using a variety of equipment, one of the most efficient and in demand is a CNC milling machine. The technique is quite complex and expensive, it is not surprising that you should choose it wisely before buying. Acron-System offers a wide range of branded equipment at affordable prices. It remains only to determine what exactly you need.Key parameters to consider when choosing a CNC milling machine

Sometimes after acquiring a machine, business owners face various problems. Let’s get to know what to consider in order to avoid such consequences..

Determining the maximum size of the workpiece. This parameter will help to calculate the size of the working field of the equipment. In order to obtain the desired result, the workpiece must be processed from all sides, due to this the quality of the work performed is increased and does not require frequent readjustment.

Machine spindle. This item is one of the most important and expensive equipment. It is better not to buy equipment from little-known manufacturers, especially if the devices are liquid-cooled. High-quality spindles with good care can last at least five years. Another important parameter is its power – it should have some margin in comparison with the expected loads..

Milling Machine Design. It is important to think about the portal, it is good that it is solid and made of cast iron. In this case, the equipment will be characterized by high resistance to vibration and increased rigidity. Some manufacturers produce them from aluminum, which leads to lower costs. However, this reduces the quality of processing..

Tool number. It is necessary to determine in advance the number of tools that will be required for the complete processing of workpieces. If their number exceeds 3, their frequent replacement may be required, then it is better to prefer equipment with automatic or semi-automatic tool change.

Portal moving engines. Motors of movement are servomotors and stepper. Units of the first type are considered the most advanced, but they are more accurate, high-speed and expensive. When processing, they do not accumulate errors. They do not have skipping steps, which are characteristic of stepper motors. Reliable manufacturers’ servomotors help increase the durability of milling machines.

Control stand. It is important to carefully examine this element. Equipment from leading manufacturers does not need to be connected to a PC and has other important advantages.

Software. It is important to study the software that the manufacturer provides with milling equipment. It’s good that they are Russified and easy to use..

As you can see, the choice of a milling machine has a number of features and criteria that should be taken into account. Having carefully studied everything, you can purchase the most suitable type of equipment.