Concrete is of course one of the most common and used building materials. The scope of its application is very extensive. One such area is the equipment of floors in buildings and structures. As we know, the floors should be perfectly flat. To solve this problem, builders in the past used various hand tools. Nowadays, with the development and improvement of construction equipment, such a tool as vibration rails comes to the fore. The use of vibration rails allows us to simultaneously solve two problems, this is the alignment of the floor, and compaction of the concrete-cement mass.

Modern industry produces two main types of vibration rails: floating and rails, during the operation of which guides are used. In this case, the vibrating rails can be made of steel materials or aluminum. The latter option is most preferable, since aluminum has a higher resistance to corrosion and, consequently, greater durability. The principle of vibrorails is simple.

Concrete is of course one of the most common and used building materials. The scope of its application is very extensive. One such area is the equipment of floors in buildings and structures. As we know, the floors should be perfectly flat. To solve this problem, builders in the past used various hand tools. Nowadays, with the development and improvement of construction equipment, such a tool as vibration rails comes to the fore. The use of vibration rails allows us to simultaneously solve two problems, this is the alignment of the floor, and compaction of the concrete-cement mass.Modern industry produces two main types of vibration rails: floating and rails, during the operation of which guides are used. In this case, the vibrating rails can be made of steel materials or aluminum. The latter option is most preferable, since aluminum has a higher resistance to corrosion and, consequently, greater durability. The principle of vibrorails is simple.

An engine is fixed on a metal or aluminum frame, the pulses from which are transmitted to the frame. As a result, vibrational vibrations of the frame occur, which in turn contribute to the leveling of the surface of the concrete mortar and the displacement of excess air from it.

Most often, gasoline or electric drives are used as the engine. Each of them has its own advantages and disadvantages. For example, vibrorails with a gasoline engine have higher performance than electric ones. Another undoubted advantage of the gas vibrorail is its independence from the presence of an electric energy source on the working platform.. Electric vibrorake for concrete less productive, but also has several advantages. One of them is low noise..

Do not forget that most of the work related to leveling floors is carried out in enclosed spaces and here electric vibrating rails come to the forefront due to the absence of harmful emissions during engine operation.

You can also distinguish vibration rails and their configuration. Depending on the design and configuration features, they can be of fixed length, telescopic and sectional. The first option is a one-piece frame with a drive. The second is a one-piece construction, but with the possibility of changing the length of the profile depending on the area of the treated surface. And sectional vibratory rails are assembled from separate sections of a certain length.

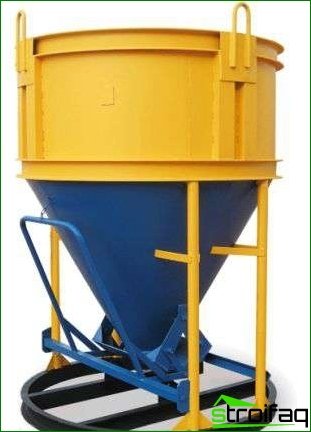

Company «RusInStroy» engaged in the supply and sale of vibration rails and has gained vast experience in this area. In addition to vibration rails, the company’s assortment also includes other equipment necessary for working with concrete mixtures and solutions, for example concrete bucket bell, deep vibrators and concrete mixers. IN «RusInStroy» models of vibration rails from the most famous manufacturers that have proven themselves in the domestic market are presented: Samsan, TSS, Wacker Neuson as well as models of our own production. You can make an order for the necessary equipment on the official website of the company or by calling.