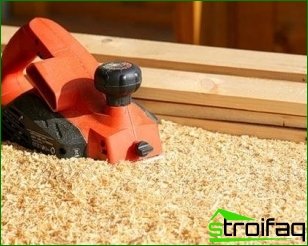

Those who planed wood using an ordinary planer are familiar with the complexity of this process. The use of electrical analogues will allow you to perform the same amount of work with minimal physical effort. If necessary, the tool can be fixed, as a result of which it turns into a planing machine.

Electric planers are highly functional and easy to use. The electric motor takes over the load, and the master only directs the operation of the equipment. With a lack of practical experience in working with an electric planer, at first small depressions may form on the surface of the product from time to time. Therefore, before performing responsible work, it is better to practice on less important structures. The electric planer allows you to perform fitting, preliminary planing, quarter selection, bevel edges, process dimensions, etc. To ensure long-term operation of the tool, as well as providing its functionality and convenience, you need choose the right electric planer.

How not to make a mistake when choosing a planer

Each electric tool can be classified into two groups: for domestic and professional use. Their main differences lie in the possibilities of continuous operation, functional features and power. In this case, there is a general rule: household models imply rare use, if the tool is often used, then it is worth investing in professional equipment.

Among the main characteristics of the electric planer are rotation speed, engine power, width and depth of processing. Choosing the right model, you need to pay attention to each of these indicators..

Those who planed wood using an ordinary planer are familiar with the complexity of this process. The use of electrical analogues will allow you to perform the same amount of work with minimal physical effort. If necessary, the tool can be fixed, as a result of which it turns into a planing machine.Electric planers are highly functional and easy to use. The electric motor takes over the load, and the master only directs the operation of the equipment. With a lack of practical experience in working with an electric planer, at first small depressions may form on the surface of the product from time to time. Therefore, before performing responsible work, it is better to practice on less important structures. The electric planer allows you to perform fitting, preliminary planing, quarter selection, bevel edges, process dimensions, etc. To ensure long-term operation of the tool, as well as providing its functionality and convenience, you need choose the right electric planer.

How not to make a mistake when choosing a planer

Each electric tool can be classified into two groups: for domestic and professional use. Their main differences lie in the possibilities of continuous operation, functional features and power. In this case, there is a general rule: household models imply rare use, if the tool is often used, then it is worth investing in professional equipment.

Among the main characteristics of the electric planer are rotation speed, engine power, width and depth of processing. Choosing the right model, you need to pay attention to each of these indicators..

The electric motor is used to work the planer: it directs the rotation of the drum, on which the knives are fixed. The tree has a heterogeneous structure, so it is better to purchase a high power tool (at least 600 W).

The electric motor transmits rotational motion to the drum using a timing belt. Over time, it wears out and needs to be replaced. Replacing this accessory is not difficult: just remove the removable side cover. Thanks to a smooth increase in speed, any overloads are excluded when the electric motor is turned on. Many planers have rotary drums that are open on one side. This solution makes it possible to select a quarter along the length of the workpiece at an angle of 90 °. Side stop allows you to select a quarter of the desired width.

Other important features

Cast aluminum is used to make the base of the electric planer. The base is divided into two sections: one in the back and the other in front of the drum. To achieve high-quality workpiece processing, you need to use a sole of perfect smoothness. If the base of the tool has a longitudinal groove, then an air cushion will not appear between the sole and the wood, so the cut will have the same thickness throughout the entire working cycle.

Like hand tools, electric planers allow you to adjust the desired cutting depth. To do this, the front section of the base is adjusted to the desired height. It can move vertically, and the movement is transmitted by the handle with divisions or a special button. The scale allows you to set the desired cutting depth, setting the accuracy to 0.1 mm. The adjustment knob often plays the role of a second handle, however, internal notches are applied on it, you can only switch modes by lifting this element. Those tools in which the handle is devoid of notches may lose their settings during operation. Depth, as a rule, can be switched in increments of 0.1 millimeters, but this characteristic may differ in different models. Many experts note that it is especially convenient when the lower value of the scale is negative. This is due to the fact that in some tools at zero value the chips are still removed. In addition, the length and width of the base affects the stability and smoothness of the electric planer.

Among the useful functions of electric planers is the ability to sample a quarter or a fold. An additional angular emphasis is intended for these purposes, limiting the planing width. Thanks to him, the angle between the plane and the bar or board is fixed. To the right of the tool, you can set the depth gauge, which will protect against excessive processing of wood. Thanks to an angular emphasis you can process a surface at angles of 45 ° and 90 °.

Having considered the main characteristics, you can choose the right electric planer. Guided by the tips from this article, you will be able to choose a tool that would fully meet your needs.