At heights of up to 100 meters, facade scaffolding is used in the construction and finishing industry. Collapsible type structures are needed to place labor and manual equipment along the walls of buildings during reconstruction, restoration, and insulation works.

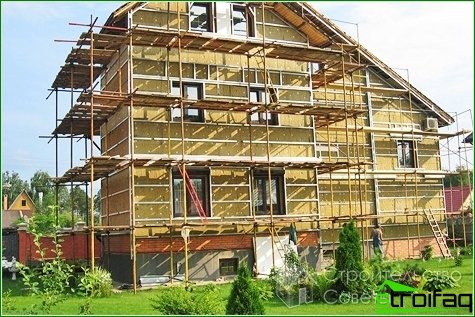

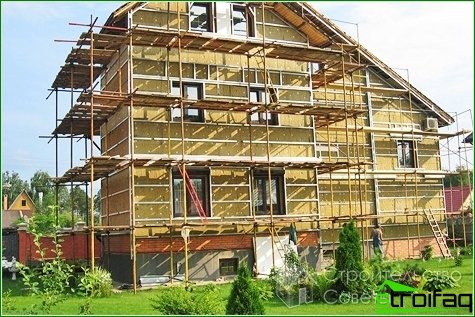

The standard material for the production of these supporting structures are steel pipes. They have a high margin of safety and are convenient for installation. The facade scaffolding is covered by GOST 27321-87. The frame of the structure, as a rule, covers the entire surface of the building being repaired (example in the photo).

Varieties of facade scaffolding

Depending on the method of assembly, structures are divided into 4 types.

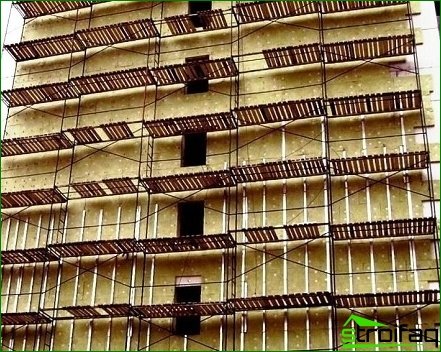

• Frame. Construction details are fastened to each other with flag type locks. Strength is provided by longitudinal and diagonal guides. The frame is attached to the wall as it is erected. This is the most common type of forest..

• Clamp. They are used on buildings of round, semicircular, multifaceted, non-standard shapes. To achieve a snug fit of the frame to the surface of the object, it is necessary to build a system of flooring, stairs, racks, shoes, supports and other elements. Fastenings are special locks — clamps.

At heights of up to 100 meters, facade scaffolding is used in the construction and finishing industry. Collapsible type structures are needed to place labor and manual equipment along the walls of buildings during reconstruction, restoration, and insulation works.

The standard material for the production of these supporting structures are steel pipes. They have a high margin of safety and are convenient for installation. The facade scaffolding is covered by GOST 27321-87. The frame of the structure, as a rule, covers the entire surface of the building being repaired (example in the photo).

Varieties of facade scaffolding

Depending on the method of assembly, structures are divided into 4 types.

• Frame. Construction details are fastened to each other with flag type locks. Strength is provided by longitudinal and diagonal guides. The frame is attached to the wall as it is erected. This is the most common type of forest..

• Clamp. They are used on buildings of round, semicircular, multifaceted, non-standard shapes. To achieve a snug fit of the frame to the surface of the object, it is necessary to build a system of flooring, stairs, racks, shoes, supports and other elements. Fastenings are special locks — clamps.

• Whip. A typical way to connect parts in this assembly method is to install supports in prepared shoes. Thus, a system of tiers is formed that is convenient for working on small, fairly smooth geometrical objects.

• Wedge. The details of such a frame are assembled by inserting supports into the grooves of multidirectional flanges. Each flange is equipped with a certain number of holes that can be directed at different angles..

Who should mount and be responsible for forest security?

The installation is best entrusted to the team of installers from the manufacturer. Professionally trained workers will erect the frame not only quickly, but also in accordance with safety rules and taking into account the particular system.

In the range of services of serious companies, customers are available not only the purchase of forests, but also the rental of ready-made kits. As a rule, the price of building a rented structure is lower than the cost of installing a structure under a contract of sale.

A guarantee of the strength and stability of the system must be specified in the contract.