Everyone who selects special equipment for the production of profiles will be able to appreciate how extensive the range of models is on sale. When deciding on a choice, it is important to evaluate the cost, as well as pay attention to all the parameters. The purpose with which it is planned to use the equipment for the production of profiles in the future also matters..

Hardware Features.

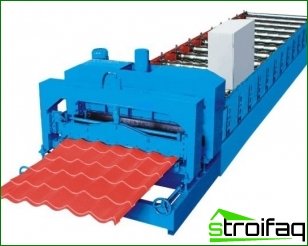

The roll forming equipment factory offers models that are distinguished by the ability to quickly complete installation. It does not take a lot of time to carry out commissioning. To carry out maintenance work, it is not necessary to involve a significant number of employees. At the roll forming equipment factory, models are created that differ in operation provided that the electronic control system is notable for its low complexity. This allows adjustments to be made to the speed of the line. This also applies to the parameters of the profiles themselves, the volume of the consignment of goods and other characteristics.

The advantages of modern equipment.

Today, models are often ordered at the roll forming equipment factory, since this allows production to be made economical with them. The choice made in favor of new equipment for the production of profiles, becomes the right and economic profitable. New models do not require the use of large premises.

There is an opportunity to produce independently the required metal profile. At the same time, quality control is carried out independently. When using equipment for the production of profiles, it will be possible to reduce the material costs associated with the purchase of building materials.

The use of roll forming equipment.

An important feature inherent in equipment for the production of profiles is the achieved convenience when using it.. Roll Forming Equipment makes it easy to carry out readjustment. As a result of such actions, the use of one line will make it possible to produce the required type of profile. If one line is used, it is possible to produce profiles that differ in their shape.

When suitable models are selected at the roll forming plant, it is important to consider the presence of certain restrictions associated with the implementation of changes to adjust the operation. The factory for bending equipment offers its customers different models. They differ in such parameters as the largest and smallest width of the metal that can be processed. The metal profiles themselves involve different types. These can be profiles that have a small thickness. You can also see sheets with a significant width..

Cost of equipment Depends on the type chosen by the buyer. The list of characteristics inherent in each of the models sold by the plant is of importance. In any case, the selected models must meet the requirements. When buying, customers will need the help of specialists. They will guide customers in the assortment of equipment and help determine the choice..